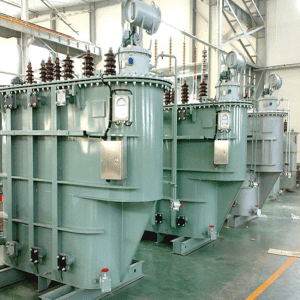

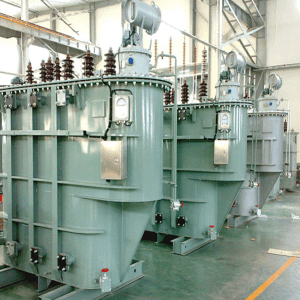

Product description

First, product features

The three-phase oil-immersed distribution transformer produced by our company adopts a new insulation structure to improve the ability to resist short circuit; The core is made of high-quality cold-rolled silicon steel sheets; The high-voltage windings are made of high-quality oxygen-free copper wire, and a multi-layer cylindrical structure is adopted; All sturdy parts have a special anti-loosening treatment.

The product has the characteristics of high efficiency and low loss, which can save a lot of power consumption and operating costs, and has significant social benefits, and is a high-tech product promoted by the state. Sales Hotline: 13508930968

2. Reliable structure

On the basis of traditional structure and mature technology, our company has made many improvements, such as:

1. Spiral coil with longitudinal oil channel, better internal heat dissipation;

2. The effective support of the end face of the coil has been improved, and the ability to resist short-circuit current is stronger;

3. The new hoisting structure and body positioning structure are adopted to ensure more reliability in long-distance transportation and operation;

4. We also have a lot of unique and reliable structures to serve you;

5. The choice of a higher performance level transformer will have a higher level of technical content.

3. High-quality materials

The oxygen-free copper wire with lower resistivity is selected, and after a series of additional surface treatment, it is smoother and has no burr sharp corners, so that the load loss of the transformer is lower and the electrical performance is more reliable.

The selection of high-quality silicon steel sheets, with the improvement of performance level, the use of silicon steel sheets with lower unit loss, so that the transformer no-load loss is lower.

The selection of high-quality laminated wood insulators, no cracking, even under the action of short-circuit current, the slightest line does not move.

The transformer oil that has undergone depth filtration is selected, and the level of water, gas and impurities is lower, and the transformer works more reliably.

The selection of high-quality rubber sealing materials can effectively prevent aging and eliminate leakage.

All raw materials have undergone quality inspection to effectively prevent aging and eliminate leakage.

All raw materials have undergone quality inspection, and all raw material manufacturers have undergone strict review in accordance with national standards ISO9000.

Fourth, the technical and economic performance is good

On the basis of S9 series, the no-load loss of S11 series products is reduced by 30% on average; The no-load current is 70-85% lower than that of S9; The average temperature rise is reduced by 10K, the service life of the product is more than doubled, and it can still operate for a long time even under the condition of 20% overload; The operating noise of the product is reduced by 2-4 decibels on average.

5. Fully sealed

Select S11 (M) R in the M means that the fuel tank adopts a fully sealed structure, the fully sealed distribution transformer compared with the ordinary oil-immersed transformer, the oil storage cabinet is canceled, the wave fin of the oil tank replaces the oil pipe as a cooling and heat dissipation element, the corrugated oil tank is manufactured by high-quality cold-rolled sheet on a special production line, the wave fin can expand and contract the volume of transformer oil, so that the transformer is isolated from the atmosphere, prevent and slow down the oil deterioration and insulation moisture, enhance the reliability of operation, and operate normally without maintenance.

The surface of the corrugated fuel tank is coated with conformal paint after degreasing, rusting and phosphating treatment, which is suitable for use in metallurgy, petrochemical, mining and other environments.

6. Transformer product standards

GB 1094.1-1996 GB 1094.2-1996 JB/T10088-2004

GB 1094.3-2003 GB 1094.5-2003 GB/T 10237-1988

GB/T 6451-2008 GB/T 7595-1987 JB/T 3837-2010

7. Normal conditions for transformer Special conditions for transformer

The altitude does not exceed 1000m; The altitude is more than 1000m;

Ambient Temperature: Ambient Temperature:

+40°C +40°C

The average temperature of the hottest month is +30°C, and the minimum temperature is -25°C

The highest average annual temperature is +20°C

The minimum temperature outside is -25°C