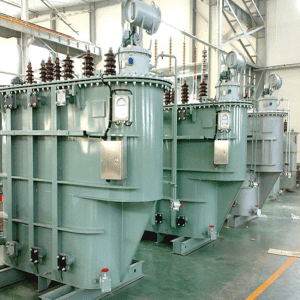

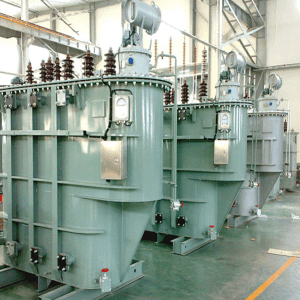

Product description

The maintenance and testing of the oil-immersed transformer after it is put into operation is very important, if the maintenance is not in place, it will directly affect the normal and safe operation of the transformer, and will cause certain damage to the oil-immersed transformer itself, thereby reducing the service life of the transformer itself, so it should be regularly repaired and tested after the transformer is put into operation. Next, Xiaobian will take you to understand the maintenance regulations and repair regulations of oil-immersed transformers.

General provisions for the maintenance of oil-immersed transformers: the maintenance of oil-immersed transformers is carried out once a year on site; There are two types of maintenance

1. Key repair: If a defect is found during inspection or maintenance, which endangers the safety of the power supply of the equipment, maintenance or treatment should be organized immediately; General repair: non-critical equipment that does not endanger the safety of power supply will be included in the monthly maintenance plan when shortcomings are found; Overhaul once every fifteen years.

The electrical inspection workshop undertakes the repair and overhaul of oil-immersed transformers, and the maintenance is carried out by the equipment maintenance department.

2. The maintenance cycle, items and requirements of oil-immersed transformers refer to the “Railway Power Management Rules”. The safety measures must meet the requirements of the “Railway Electric Power Safety Work Regulations” to ensure the safety of personnel and equipment.

3. The maintenance of oil-immersed transformers should be investigated before repair, inspected during repair and accepted after repair. Master the working status of the oil-immersed transformer, grasp the existing shortcomings, and determine the maintenance items. According to the inspection during repair, find and correct the problems in the maintenance in time. After the repair, the person in charge of the project shall organize the maintenance personnel and the person responsible for the equipment to participate, and make a record of the acceptance. After the operation of the oil-immersed transformer for maintenance, the power transmission inspection should be carried out, and the work can be completed when everything is normal. Oil-immersed transformer maintenance should be recorded. Pre-repair investigation, maintenance records, and inspection records should be compiled into the technical files of oil-immersed transformers. And do the named maintenance, for future reference.

After the transformer is put into operation, 2~3 months after the inspection, 1 inspection is carried out every year, and most of the inspection contents are: (1) check whether the operation of instruments and protection devices such as pointer thermometers of oil-immersed transformers is normal;

(2) Check whether the core air duct of the oil-immersed transformer is blocked by dust and foreign matter, and whether there is rust or corrosion;

(3) Check whether there is dust accumulation, cracking, discoloration, discharge and other phenomena of pouring winding and interphase connection lines, and whether the insulation resistance is normal;

(4) Check whether the winding and pressing device is loose;

(5) Check whether the contacts of the voltage regulating tap-changer have overheating, discoloration, poor contact or rust.

(6) Check whether the cooling device of the oil-immersed transformer including the motor and fan bearings is in good condition.

General requirements for repairs:

1. If the body of the transformer is inspected under outdoor conditions, relevant rainproof and dustproof measures must be taken, and temporary tents or sheds must be built if necessary.

2. If the transformer is overhauled, the relevant records must be made, as follows: first, record the situation of the equipment before maintenance, such as: the legacy of the last maintenance and its shortcomings;

3. If the temperature of the surrounding air is less than or close to the temperature of the body when checking the body of the transformer, if the temperature of the surrounding air is less than 10 °C, the temperature of the body can be heated to increase the temperature of the body, and the temperature of the surrounding air is generally 10 °C lower than the temperature of the body of the transformer.

4. The time of the gas exposed to the body of the transformer should follow the relevant requirements, for the dry temperature, that is, the relative humidity is not more than 65% of the climatic conditions, generally should not exceed 16h, for the humid weather, that is, the relative humidity is not more than 75%, generally should not exceed 12h, if the specific time of a transformer exposed to the air does not meet the relevant regulations, the body should be invaded into the insulating oil to avoid moisture.