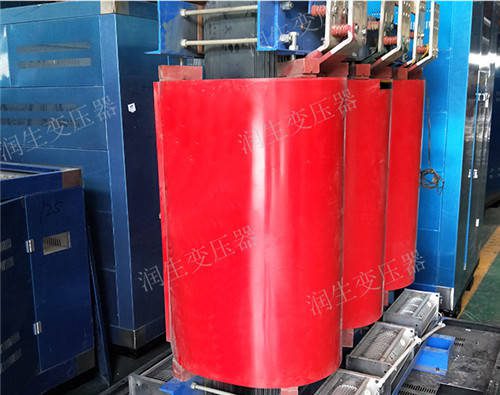

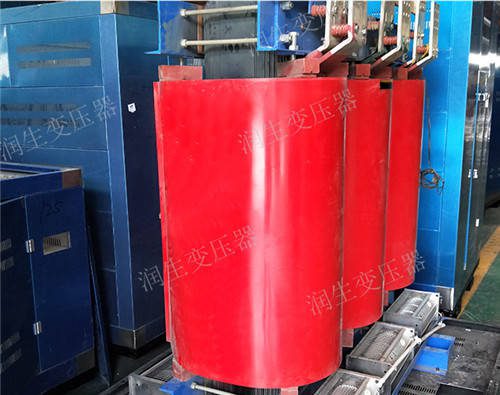

Product description

SCB13-200KVA dry-type power transformer to SCB11 transformer standard specification of improved products, it and SCB10/SCB11 transformer appearance and structure are not different, the key difference is that the SCB13 dry-type transformer no-load loss will be 30% lower than SCB10 transformer and 20% lower than SCB11 transformer, SCB13-200KVA dry-type power transformer overall energy-saving effect is better than SCB10/ SCB11 transformer (transformer consumption = transformer no-load loss + transformer load loss).

Structure of SCB13-200KVA dry-type power transformer:

1. The coil is coiled or foil-wound with copper wire, improved by glass fiber, and the epoxy resin is poured without filler, vacuum drying, degassing, dehumidification, high impact toughness, short circuit resistance, and strong impact resistance.

2. The head and tail end of the high-voltage winding and the middle tap tap are made of copper insert embedded structure, with good rigidity, easy to adjust the gear, beautiful and neat.

3. The core is made of high-quality grain-oriented cold-rolled silicon steel sheets, and the 45-degree full-oblique multi-step joints. The surface layer is covered with resin insulating coating, which is resistant to moisture and cold, rust prevention and noise reduction.

4. The elastic parts are clamped between the core, the clamp and the coil to make the coil in a stable clamping situation to reduce noise.

5. The transformer is designed according to self-cooling, and a longitudinal ventilation channel is reserved inside the overall poured high (low) voltage coil cylinder wall, which can be equipped with forced air cooling equipment (cooling fan), and the output volume can be increased by 20% after the forced air cooling equipment is selected.

6. Equipped with a thermostat, a platinum resistance (Pt100) is placed in the embedded hole above the low-voltage coil. In order to detect the winding temperature of the transformer, start and stop the cooling fan, and set up fault alarm, overheating report and overheating tripping functions, it provides reliable overload protection devices for dry-type transformers, and then improves the operation safety of dry-type transformers.

Features

, fireproof, zero pollution, can operate directly in the load center.

Using German HTT technology, high impact toughness, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, service life factory.

Low loss, low noise, significant energy-saving effect, maintenance-free.

It has good heat dissipation performance and strong overload capacity, and can increase the volume operation when forced to air cooling.

It has good moisture resistance and is suitable for operation in high humidity and other extreme environments.

A complete temperature monitoring and protection system can be configured. The intelligent signal temperature control system can automatically monitor and patrol the operating temperature of the three-phase winding, and can automatically run and terminate the fan.

And there are function settings such as reporting and tripping.

Small size, light weight, less floor space, low installation costs.

The core is made of high-grade cold-rolled silicon steel, 45-degree stepped full miter joint structure, and the three-shear and two-punch core angular cross-shear process and the five-step stepper shear and stacked iron process are used to optimize the magnetic flux distribution at the interface and reduce the vibration energy of the core. The core is sealed with an integrated dry solid and surface insulating resin, which effectively reduces no-load loss, full-load flow and core noise.

The high-voltage coil is wound with high-grade F-class insulated wires and international advanced insulating materials, and the larger volume coils are equipped with heat exhaust air ducts along the radial direction. This structure has good resistance to current impulse, temperature change, cracking and excellent heat dissipation. It adopts a multi-stage segmented barrel structure, which has a strong overpressure bearing capacity and a very low partial discharge level. The coil mold is poured after vacuum drying.

The whole pouring and drying process is completed according to the pre-programmed process curve, and the precise process management ensures that the coil is free of porosity and cavities.

The low-voltage coil adopts the foil structure, which efficiently solves the problem of unbalanced ampere turns of the low-voltage and high-current coil using the wire winding type, and the foil coil will not have the number of radial turns and the radial winding helix angle, which efficiently avoids the axial force of the transformer when the short circuit is made, and ensures that the current intensity in the coil can be adjusted freely along the radial direction according to the load of the high-voltage coil, which reduces the radial force when the low-voltage sudden short circuit is reduced. The top of the wound coil is sealed with resin to avoid the entry of various foreign substances and moisture.

Terms of use

a. Altitude

The altitude does not exceed 1000m.

b. Operating temperature

* High temperature +40°C

*High daily average temperature +30°C

* High annual average temperature +20°C

*Low temperature -30°C (for outdoor transformers)

*Low temperature -5°C (for indoor transformers)

c. Wave type of the supply current

The waveform of the supply current is close to that of a sine wave.

d. Symmetry of multiphase supply currents

The supply current to which the multiphase transformer is connected should be similarly symmetrical.