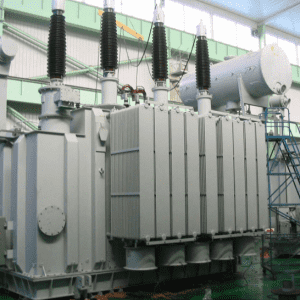

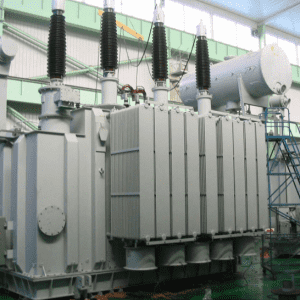

Product description

The safe operation and service life of SCB11-5000KVA dry-type transformer mainly depends on the reliability of transformer winding insulation. The winding temperature of SCB11-5000KVA dry-type transformer is higher than the ambient temperature of the insulation layer and the insulation layer is destroyed, which is one of the main reasons why the SCB11-5000KVA dry-type transformer can not work normally, so it is very important to monitor the operating environment temperature of SCB11-5000KVA dry-type transformer and report the operation.

Benefits:

1. The electromagnetic coil is coiled or foil-wound with copper wire, reinforced with glass fiber, epoxy resin glue is poured without filler vacuum dryer degassing and dehumidification, with high mechanical strength, anti-short-circuit fault and strong impact resistance.

2. The head and tail end of the high-voltage winding and the middle tap tap are made of copper insert embedded parts, with good stiffness, which is conducive to file adjustment, beautiful and generous and neat.

3. The core is stacked with a grain-oriented cold-rolled ferrite core, and the 45-degree full-oblique multi-step joint. The surface is covered with epoxy resin insulation coating, which is moisture-resistant, anti-rust treatment, and noise reduction.

4. The connecting shaft is clamped between the core, the clamp and the electromagnetic coil to make the electromagnetic coil in a stable clamping situation to reduce noise.

5. According to the over-temperature protection design scheme of the transformer, the internal structure of the material layer of the overall pouring high (low) voltage electromagnetic coil is pre-embedded with a longitudinal ventilation channel, which can be equipped with forced air-cooled equipment (high-temperature fan), and the output volume can be increased by 20% after the forced air-cooled device is selected.

6. Equipped with a temperature controller, a platinum thermal resistance (Pt100) is placed in the embedded hole above the low-voltage electromagnetic coil. In order to detect the winding temperature of the transformer, start and stop the high-temperature fan, and be equipped with fault warning, overheating alarm and over-temperature power-off, it provides reliable overload protection device for the dry-type transformer, and then improves the operation safety of the dry-type transformer.

Product Construction:

1. Iron core: the core of the imported cold-rolled ferrite core, the three-order full oblique seam structure, the core column is bundled with F-grade non-weft belt, and the core is wrapped with epoxy resin glue, which reduces the no-load loss, no-load current and white iron sheet noise, and the clamp and tight return parts are treated with a special surface layer, so that the appearance quality of the product is further improved.

2. Temperature control system and air cooling system: the high-temperature fan with scattered flow top blowing is selected, which has the advantages of low noise, high air pressure and beautiful appearance, which improves the load capacity of the transformer. The temperature control uses an intelligent thermostat to improve the operation of the transformer.

3. Maintenance of the shell and the outgoing busbar of the group: the maintenance of the chassis for further safety protection of the transformer, the waterproof level is IP20, IP23, etc. The casing material is aluminum alloy profile, cold-rolled plate, stainless steel, etc. for users to choose. The low-voltage group outlet is discharged with a standard busbar, and both the side group outlet and the top outlet can be used, and a unique group outlet method can also be configured for the user.

SCB11-5000KVA dry-type transformer is safe, flame retardant and fire safe, and can be installed directly in the load center. Durable and easy to install. It has good moisture-proof performance and can be put into use without pre-drying after stopping operation. SCB11-5000KVA dry-type transformer has low loss, low partial discharge, low noise, and can operate at 120% rated value in forced air-cooled environment. It is equipped with a complete automatic control system for over-temperature protection to provide scientific guarantee for the safe operation of the transformer. The reliability index of this product has reached the highest level in China.