Product description

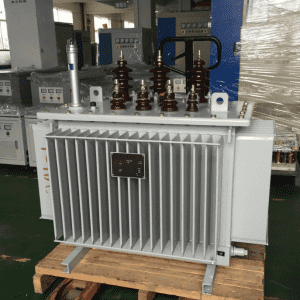

SCB10-50KVA dry-type transformer is safe, flame retardant, fireproof, pollution-free, and can be installed directly in the load center. Maintenance-free and easy to install. It has good moisture-proof performance and can be put into operation without pre-drying after being out of operation. SCB10-50KVA dry-type transformer has low loss, low partial discharge, low noise, and can be 120% under forced air cooling conditions Rated load operation. It has a complete temperature protection control system to provide reliable guarantee for the safe operation of the transformer. The reliability index of the product has reached the advanced level.

Process characteristics of SCB10-50KVA dry-type transformer

The core of SCB10-50KVA dry-type transformer is made of Shanghai Baosteel 30P105 and 120 high-quality cold-rolled silicon steel sheets, 45-degree stepped full miter joint structure, and the three-shear and two-stroke core angle-removing cross-cutting process and the five-step stepper shearing and iron-stacking process are used to improve the magnetic flux distribution at the joint and reduce the vibration energy of the core. The core is cured in one piece and sealed with insulating resin on the surface, which effectively reduces the no-load loss, no-load flow and core noise.

The high-voltage coil is wound with high-quality Class F insulated wires, and the larger capacity coil is equipped with a heat dissipation airway along the axial direction. This structure has good resistance to current impulses, temperature changes, cracking and excellent heat dissipation. It adopts a multi-stage segmented cylindrical structure, which has a strong overvoltage bearing capacity and a very low partial discharge level. The coil is poured after vacuum drying, and the whole is poured and cured

The process is completed according to the pre-programmed process curve, and the precise process control ensures that the coil is free of porosity and cavities.

The low-voltage coil adopts a foil structure, which effectively solves the problem of ampere turn imbalance of low-voltage and high-current coils using wire-wound type, and at the same time, the foil coil does not have the axial turn number and axial winding helix angle, which effectively eliminates the axial force of the transformer when the short circuit is made, and ensures that the current density in the coil can be adjusted freely along the axial direction according to the load distribution of the high-voltage coil, reducing the low voltage

Radial force in the event of a sudden short circuit. The end of the coil is sealed and cured with resin to prevent the ingress of various foreign substances and moisture.

Reference standards

GB/T10228-2008

GB6450-1986

IEC726 “Dry-type Power Transformers” (*** Electrical Standard)

GB1094-2007

SCB10-50KVA Technical Specification for Dry-type Transformer

Capacity range: 80-2500kVA

Voltage level: 10kV

Regulating mode: ±2 × 2.5% or ±5%

●:50HZ

Number of phases: 3 phases or single phase

LINK GROUP LABEL: Y,there or D,yn11

Impedance voltage: The standard impedance voltage is shown in the technical parameter table

Conditions of use: the ambient temperature is not higher than 40 °C, the relative humidity can reach ***, the altitude is not more than 1000 meters, indoor, the air exchange volume is calculated according to the total loss of the transformer, not less than 4m3/KM.min