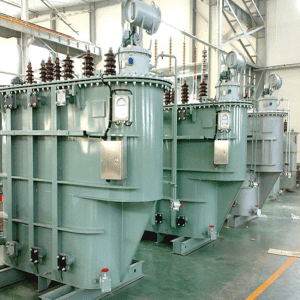

Product description

S20-16000KVA oil-immersed transformer is a large-scale power equipment, which is widely used in step-up and step-down applications in power systems. These transformers have high capacities and voltage levels to meet the needs of large-scale power systems. The following is a detailed introduction to the transformer, including its working principle, structural characteristics, use and maintenance, etc.

First, the working principle

The working principle of the S20-16000KVA oil-immersed transformer is the same as that of the S20-10000KVA oil-immersed transformer, which is based on the principle of electromagnetic induction. When alternating current passes through the primary side, a changing magnetic field is generated, which is transmitted to the secondary side through the core. On the secondary side, due to the change in the magnetic field, an induced electromotive force is generated, which enables a voltage change.

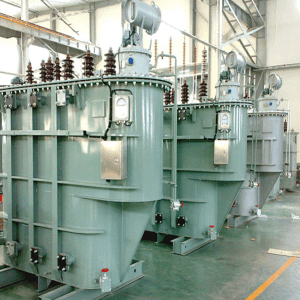

Second, structural characteristics

As a large transformer, the structural characteristics of S20-16000KVA oil-immersed transformer are as follows:

Iron core: The transformer is made of high permeability silicon steel sheets, which has the characteristics of low hysteresis loss. The shape and structure of the core are optimized to reduce reluctance and eddy current losses and improve the efficiency of the transformer.

Fuel tank: The oil tank is the shell of the transformer, which is welded with high-quality steel plate, which has good anti-corrosion performance and mechanical strength. The inside of the tank is filled with transformer oil for insulation and heat dissipation.

Winding: Winding is an important part of the transformer, which is wound with copper wire or aluminum wire. The primary side winding and secondary side winding of the transformer are connected to the power supply and load respectively to realize the voltage transformation.

Radiator: In order to reduce the temperature inside the transformer, the transformer uses a large radiator to dissipate heat through natural convection or forced ventilation. The structure of the radiator is optimized to improve heat dissipation efficiency.

Transformer oil: This transformer adopts special insulating oil, which has high electrical insulation strength and good stability. Transformer oil plays the role of insulation and heat dissipation in the transformer, which can effectively extend the service life of the transformer.

3. Use and maintenance

In order to ensure the normal operation and service life of the S20-16000KVA oil-immersed transformer, the following measures need to be taken:

Installation environment: The transformer should be installed in a dry, well-ventilated place, no violent vibration, no corrosive gas. At the same time, it is necessary to regularly clean up the surrounding debris and dirt to ensure the normal operation of the transformer.

Regular inspection: The transformer should be checked regularly, including oil level, oil temperature, winding temperature and other parameters. If an abnormality is found, it should be dealt with and recorded in a timely manner.

Maintenance: The transformer should be maintained regularly, including cleaning the oil tank, replacing the filter, etc. At the same time, the grounding of the transformer needs to be checked regularly to ensure safe operation.

Precautions: When operating the transformer, you should pay attention to safety to avoid electric shock accidents. At the same time, it should be avoided to place flammable materials around the transformer to avoid causing fire.

Spare parts replacement: When damaged, the corresponding spare parts should be replaced in time, such as windings, radiators, etc. When replacing spare parts, spare parts that match the original equipment should be selected to ensure the normal operation and service life of the transformer.

Recording and reporting: A sound recording and reporting system should be established to monitor and record the operation of the transformer in real time. When an abnormal situation is found, it should be reported to the relevant departments for handling in a timely manner. At the same time, the operation and maintenance of the transformer should be regularly reported to the superior leaders.

Training and education: Operators should be trained and educated to master the operating procedures and maintenance knowledge of transformers. At the same time, safety awareness education should be strengthened to ensure the safety and health of operators.

In short, S20-16000KVA oil-immersed transformer, as a large-scale power equipment, needs to strictly comply with relevant regulations and operating procedures during use and maintenance. Through the establishment of a sound system and strengthen training and education and other measures, the normal operation and service life of the transformer can be ensured, and the stable operation of the power system can be guaranteed.