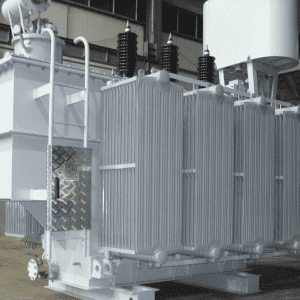

Product description

The S13 transformer is a three-phase transformer consisting of three separate single-phase transformers. Usually the method of wrapping the iron core around the winding resistance is used to form a ring of winding resistance, which is called “cylindrical winding structure”. The S13 transformer represents the performance parameters of the transformer, where “S” indicates three phases and “13” indicates its typical voltage conversion ratio of 9/0.4KV.

The working principle of the S13 transformer

The working principle of the S13 transformer conforms to the law of electromagnetic induction, and the mutual inductance effect is used to complete the conversion of voltage and current between power supplies. When the current in the main winding changes, a magnetic field is obtained in the core. This shift in the magnetic field results in a potential difference and current in the secondary winding, which in turn enables the voltage to be regulated.

Efficacy of the S13 transformer

The S13 transformer is mainly used in transmission and distribution systems, where high-voltage transmission lines are introduced into distribution stations, then step-down through transformers, and then distributed to individual customers. At the same time, it can also improve the reliability and anti-interference of the power grid, and ensure the safe operation of the power grid.

S13 transformer features:

(1) It has significant energy-saving effect: the no-load loss of S13 is about 30% lower than that of S11 transformer, and the energy-saving effect is obvious.

(2) Strong environmental protection effect: the design magnetic flux density of S13 transformer is smaller than that of S11, and the noise of the transformer is lower than that of S11, and its green environmental protection effect has been widely recognized.

(3) Low comprehensive application cost.

(4) Stable operation and high safety factor.

Compared with S11 type, the no-load loss is reduced by 25%, the no-load current is reduced by 35%, and the annual cost is reduced by 10.5%. The core material is made of high-quality silicon steel sheet with high magnetic permeability and low loss, and the structure is a frame structure with drawing rod clamping rigidity, with stable performance, low noise and strong anti-short circuit ability. The winding resistance is made of high-quality oxygen-free copper wire, which has good conductivity and low load loss. The body is clamped with high-toughness electrical laminate, all wires are firmly clamped, and the stays and backings are made of high-density insulating cardboard to optimize the electric field distribution of the transformer.