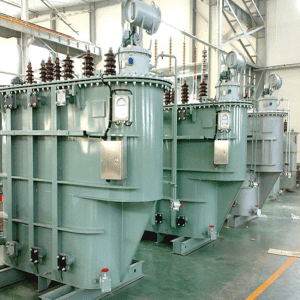

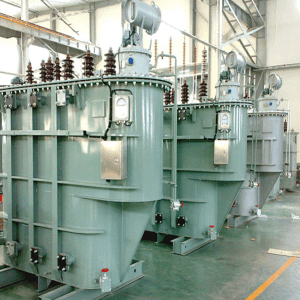

Product description

Product Introduction

The S11 transformer is suitable for three-phase, 50Hz, power grid systems. The S11 transformer is used for the input of the primary side and the output of the secondary side of the power grid. This series of transformers meet IEC60076, GB/T6451, GB1094 and other domestic and foreign specifications.

Product Advantages:

1. The core is made of high-quality and low-loss cold-rolled silicon steel sheet, and the three-stage and five-step miter joint structure is adopted, and our company has advanced slitting and cross-cutting lines, which can ensure the automatic cutting of this type of sheet, compared with the general structure, the consumption is reduced by 7~10%, and the no-load current is reduced by more than 30%;

The 2-coil wire is made of oxygen-free copper magnet wire, which increases the application range of the layer coil, and adds a radial solid oil channel. Compared with ordinary pie coils, it has the following characteristics:

a. Large plot ratio

b. The winding process is simple and the manufacturability is good

c. It has a strong vertical capacitance, which improves the voltage distribution under the influence and improves the lightning resistance characteristics

d. Because it is a radial oil channel, the heat exhaust efficiency is high

e. The ampere-turn balance is better, and the radial mechanical force is smaller

f. The selection of excellent sheet radiator fuel tank not only ensures better heat dissipation performance, but also promotes the transformer to greatly reduce the volume and beautiful appearance

3. All products adopt a three-level testing system, that is, self-inspection by operation technicians, workshop inspection, and special inspection to ensure the high quality of products;

4. The densification process is selected for the insulators to ensure that the shrinkage of the insulators is at the minimum level;

5. The introduction of domestic advanced drying system to carry out dry irritability solution, this system uses the change principle of gasoline, with gasoline as the substance, the water molecules of the transformer insulation can be squeezed from the deep insulation, and the drying is complete and fast. The preheating, vacuuming, and final water flow stages of this system are all automatically controlled by the microcomputer, and the vacuum value can reach 6Pa, and it has services such as self-inspection of faults and field diagnosis.

S11 transformer performance characteristics:

S11 transformer volume range of 30kVA~2500kVA, in 10KV, 50HZ transmission and distribution system, can be widely used in multi-storey buildings, commercial centers, subways, airports, stations, factories and mining enterprises, drilling platforms, oil production platforms, especially for flammable, explosive and other high fire requirements and difficult environment applications. It can also be used for residential areas, commercial streets, factories and mines, and rural power and lighting.

Robust and maintenance-free operation. The sealed transformer cover and the edge of the box are bolted or welded to prevent oil and air contact, and the insulation will not return moisture, which greatly reduces the insulation aging rate and improves the service life.

The design structure is simple and the operating noise is low. Due to the use of new materials and new processes, noise is reduced, there is no oil conservator, and the height is lower than similar products. There is no need to change the oil during the normal life cycle, which improves the safety and stability of the operation on the network.

The corrugated fuel tank is small in size and beautiful in appearance. When the oil temperature changes, the change of oil volume is adjusted by the elastic expansion and contraction of the corrugated sheet.

No core and oil testing. When the transformer is encapsulated, the vacuum filtration oil injection process is used to completely remove the moisture in the transformer oil. After sealing, the inside of the transformer does not touch with the gas, which effectively prevents oxygen and moisture from entering the transformer and causing the insulation performance to be reduced.