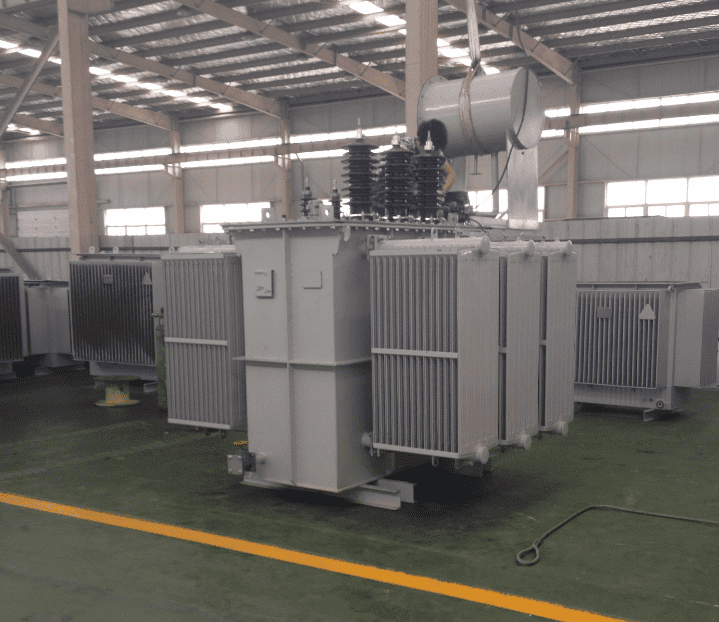

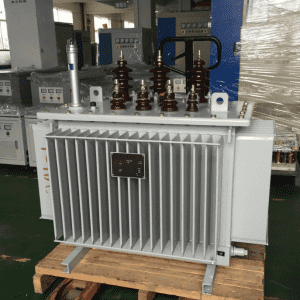

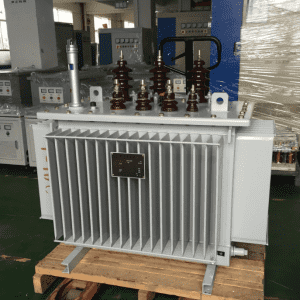

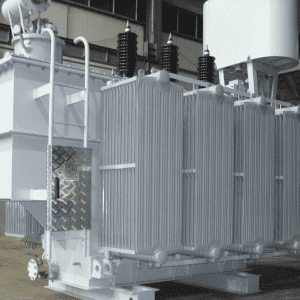

Product description

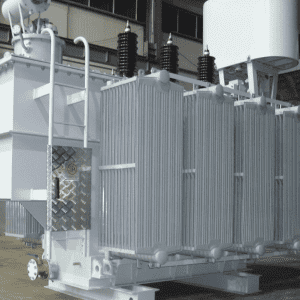

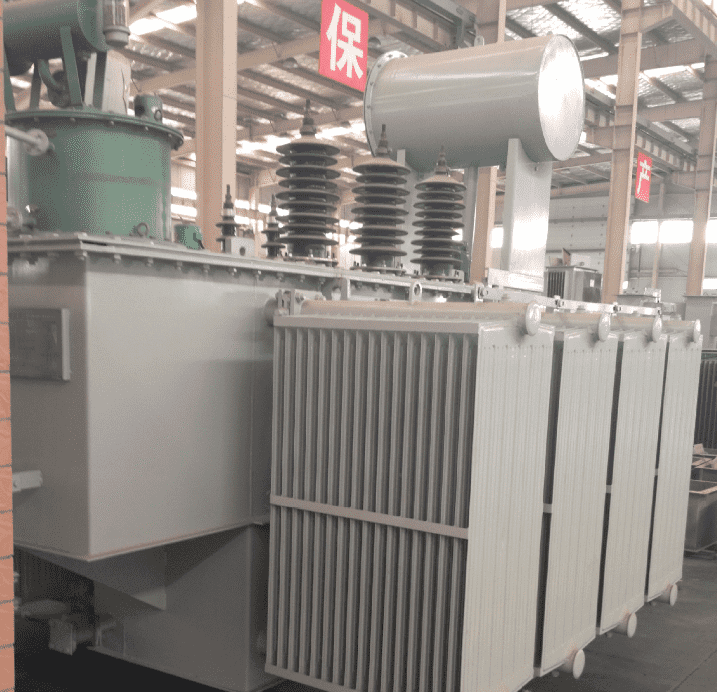

The 10KV oil-immersed transformers produced by the company are:

S11-30/10、S11-M-30/10, S11-50/10、S11-M-50/10, S11-63/10、S11-M-63/10,

S11-80/10、S11-M-80/10, S11-100/10、S11-M-100/10, S11-125/10、S11-M-125/10,

S11-160/10、S11-M-160/10, S11-200/10、S11-M-200/10, S11-250/10、S11-M-250/10,

S11-315/10、S11-M-315/10, S11-400/10、S11-M-400/10, S11-500/10、S11-M-500/10,

S11-630/10、S11-M-630/10, S11-800/10、S11-M-800/10, S11-1000/10、S11-M-1000/10,

Standards for the implementation of oil-immersed transformers:

GB1094.1 “Power transformers – Part 1 General provisions”;

GB1094.2-1996 “Power transformers – Part 2 Temperature rise”;

GB1094.3-2003 Power transformers – Part 3 Insulation level, insulation test and air gap for external insulation

GB1094.4-2003 Power transformers – Part 10 Sound level identification

GB/T6451-2008 “Technical Parameters and Requirements for Oil-Immersed Transactors” and entrustment requirements

GB1094.5-2003

GB/T15164 “Load Guidelines for Oil-Immersed Power Transformers”

IEC76 Power Transformers

GB2536 “Transformer Oil”

S11-1250/10、S11-M-1250/10, S11-1600/10、S11-M-1600/10, S11-2000/10、S11-M-2000/10,

Conditions of use of oil-immersed transformers:

1. Use altitude: H<1000m

2. Working ambient temperature: -25°C~+40°C

3. Relative humidity: when the air is +25°C, the relative humidity does not exceed 90%

4. Wind speed: <35m/s

5. Seismic acceleration: horizontal acceleration is 0.4m/s²

6. Workplace: no fire, explosion hazard, chemical corrosion level severe vibration occasions

Introduction to the quality assurance system

Product quality is the eternal theme of Xuzhou Debang Power Equipment Co., Ltd. According to the ISO9001 quality standards, the company has established and improved the quality management system, and obtained the quality management certification in 2013.

1. Committed to technological progress and optimization of resource allocation

Implement a planned update to ensure that resources are available to meet the needs of management, execution of work and activities. The company focuses on improving the ability to guarantee resources from the following aspects, and incorporates them into the medium and long-term development plan:

●Timely supplement and equip technical management personnel and operators, strengthen the education and training of employees’ quality awareness and professional and technical level, so that each employee understands that the goal of work is to provide high-quality products and customer satisfaction, and have the ability to undertake the realization of goals.

●Continuously equip and update design, research and manufacturing equipment, enrich and improve monitoring equipment and means, and implement the application of computer redesign, production, testing and operation management, so as to provide good hardware support for the company’s quality assurance

2. Develop and design products to meet user needs

In order to provide design quality, our company has been in strict accordance with the ISO9001 quality assurance system since 2013 to review the design plan and process plan, engineering designers widely use computers to assist in design, drawing, and focus on electric field, magnetic field, humidity field, fuel tank strength, wave process and noise reduction research and design, to ensure that the product meets user requirements.

3. Strengthen quality awareness and try quality control

Quality control of the supplier side is an important part of controlling procurement activities and ensuring product quality. The company focuses on the quality control of the supplier of the main raw materials and purchased parts, in accordance with the principle of “advanced technology, stable quality, reasonable price, thoughtful service, timely delivery”, the supplier is evaluated, fixed and sorted, and regularly re-evaluated, and at the same time the purchased items are strictly inspected to ensure the quality of the purchased items and achieve the company’s quality objectives.

4. Analyze the production process and improve the level of production technology

The company not only has advanced and complete production equipment, but also introduces and absorbs innovative advanced manufacturing technology. When the process department carries out process planning, it implements strong control over factors such as people, machines, materials, methods, rings, and testing that affect the quality of the process. On the basis of process analysis, the key processes, special processes, and control points that directly affect product quality are controlled, and effective operation quality documents and process rules are issued to the required positions to establish a quality view of “meticulous” and “the next process is the user of the previous process”, so as to ensure that the production and service process of the product is under control from beginning to end.

5. The inspection of the product is meticulous, and the main test is scientific

The company implements the “three inspections” system of self-inspection, mutual inspection and special inspection, and strictly controls the quality. The quality inspection department shall conduct inspections in accordance with the inspection points specified in the quality plan, according to the testing procedures, and ensure that the specified requirements are met. Before the product is shipped and delivered, the finished product inspector must inspect and count the products to be shipped to ensure that the items are complete and the packaging quality meets the requirements, so as to ensure that the delivered products satisfy the users.

6. Improve quality measures and do a good job in after-sales service

The company has established a sound after-sales service system and quality management system, regularly held regular quality meetings and quality analysis meetings, timely feedback, statistics, analysis, and processing of the quality department, taken effective corrective and defensive measures, and cooperated with a strong quality reward and punishment system to ensure that the company’s quality system is scientific and reasonable, and is fully realized in the operation process, so as to promote the stability and improvement of product quality

A method to improve the resistance of transformers to short circuits

In order to improve the short-circuit resistance of transformers, our company has adopted the following effective methods

◆ The introduction of international advanced technology fully considers the various situations when the product bears short circuit and solves it in a targeted manner, and adopts a series of measures such as rigid positioning on six sides of the body to maintain the overall stability of the product.

◆ The design adopts dynamic force calculation to assess the dynamic and thermal stability of the product; Set up a separate voltage regulating coil to strictly ensure the ampere-turn balance of the high and low coils, and at the same time maintain the consistency of the magnetic center of the high, low and voltage regulating coils, so that the short-circuit electric power is minimized;

◆ The low-voltage coil directly winds the high-strength bobbin, and the high, low, and voltage-regulating coils adopt a compression device in the radial and axial directions when winding, and the outer diameter side adopts a locking brace to increase radial firmness measures;

◆ The coil is dried by pressure vacuum, assembled as a whole, and the coil height is repeatedly adjusted during the reassembly process to ensure that the final high and low pressure coil height is completely consistent, that is, the coil is stabilized. The axial strength of the coil is improved by pre-densification of all cushion blocks, chamfering and deburring, evenly arranging the compression parts of the body to ensure mechanical strength and sufficient compression force

◆ High voltage, low voltage, voltage regulating coil winding to ensure that the geometric size of the coil itself is accurate, the assembly center between the coil and other parts of the scale of the scale of the tight, between the paper tube and the core with a brace rod solid support, coil set to adopt a series of combination technology in the spokes to bundle and solidify, and each part will not be channeled and unstable deformation when subjected to short-circuit electric power

◆ The lead wire is fixed to strengthen the encryption, and the parts adopt self-locking and anti-loosening structure to meet the dynamic and thermal stability in the event of short circuit.

◆ The radial fastening of the coil adopts the “zero” margin design, and the iron core and the low-voltage coil paper tube, between the low-voltage, high-voltage, voltage-regulating coil and between the support bar and the coaming plate are evenly and fully dried, and the close fit ensures that the whole coil has excellent tightness and concentricity.

◆ The insulating materials are stored in strict and standardized drying and sealing at all stages of raw materials, semi-finished products and final assembly of the body to avoid uncontrollable moisture absorption, expansion and deformation and size changes, such as: insulating cardboard and post-processing cushion blocks, pressure rings, etc., all of which are sealed and stored in a special constant temperature drying cylinder.

◆ After the drying of the body is completed, it is strictly followed by the exposure time in the atmosphere to avoid the expansion and deformation of the insulator absorbing a large amount of water.