Product description

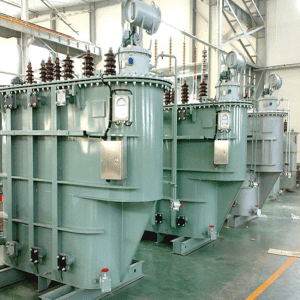

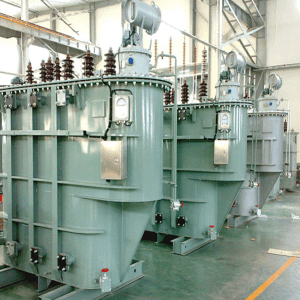

All copper oil-immersed transformer S11-200kva oil-immersed transformer, all copper material, manufacturer spot direct sales, reliable quality to sign a quality contract!

Performance characteristics:

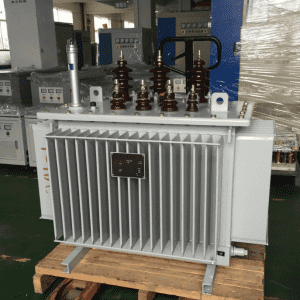

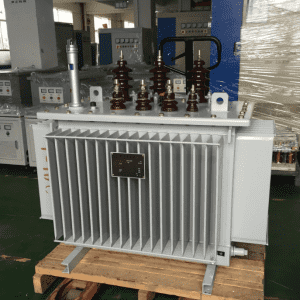

a. In addition to the copper wire used for small capacity, the low-voltage winding of oil-immersed transformer generally adopts a cylindrical structure of copper foil winding and pumping; The high-voltage winding adopts a multi-layer cylindrical structure, so that the ampere-turn distribution of the winding is balanced, the magnetic flux leakage is small, the mechanical strength is high, and the short-circuit resistance is strong.

B. The core and winding have adopted fastening measures, and the fastening parts such as the height and low-voltage lead are equipped with self-locking locknuts, and the non-hanging structure is adopted, which can withstand the shock of transportation.

c. The coil and core are dried by vacuum, and the transformer oil adopts the process of vacuum oil filtration and oil injection, so that the moisture inside the transformer is minimized.

d. The oil tank adopts corrugated sheets, which has a breathing function to compensate for the volume change of oil caused by temperature changes, so the product does not have an oil conservator, which obviously reduces the height of the transformer.

e. Because the corrugated sheet replaces the oil conservator, the transformer oil is isolated from the outside world, which effectively prevents the entry of oxygen and water from leading to the decline of insulation performance.

f. According to the above five performances, it ensures that the oil-immersed transformer does not need to change oil during normal operation, which greatly reduces the maintenance cost of the transformer and prolongs the service life of the transformer.

Installation points

The distribution transformer is an important component of the substation, and the oil-immersed transformer is generally installed in a separate transformer room.

Relying on oil as the cooling medium, such as oil immersion self-cooling, oil immersion air cooling, oil immersion water cooling and forced oil circulation. Generally, the main transformer of the booster station is oil-immersed, with a conversion ratio of 20KV/500KV, or 20KV/220KV, and the factory transformer used by the general power plant to drive its own load (such as coal mill, induced draft fan, blower, circulating water pump, etc.) is also an oil-immersed transformer, and its conversion ratio is 20KV/6KV.

Oil-immersed transformers are hermetically sealed with full oil filling. The corrugated oil tank shell adapts to the expansion of the oil with its own elasticity and is a permanently sealed oil tank, and the oil-immersed transformer has been widely used in various power distribution equipment.

Cooling method

In the operation of oil-immersed power transformers, the heat from the windings and iron core is first transferred to the oil, and then to the cooling medium through the oil. The cooling methods of oil-immersed power transformers can be divided into the following types according to the size of the capacity:

1. Natural oil circulation and natural cooling (oil immersion self-cooling type)

2. Natural oil circulation air cooling (oil immersion air cooling)

3. Forced oil circulating water cooling

4. Forced oil circulating air cooling

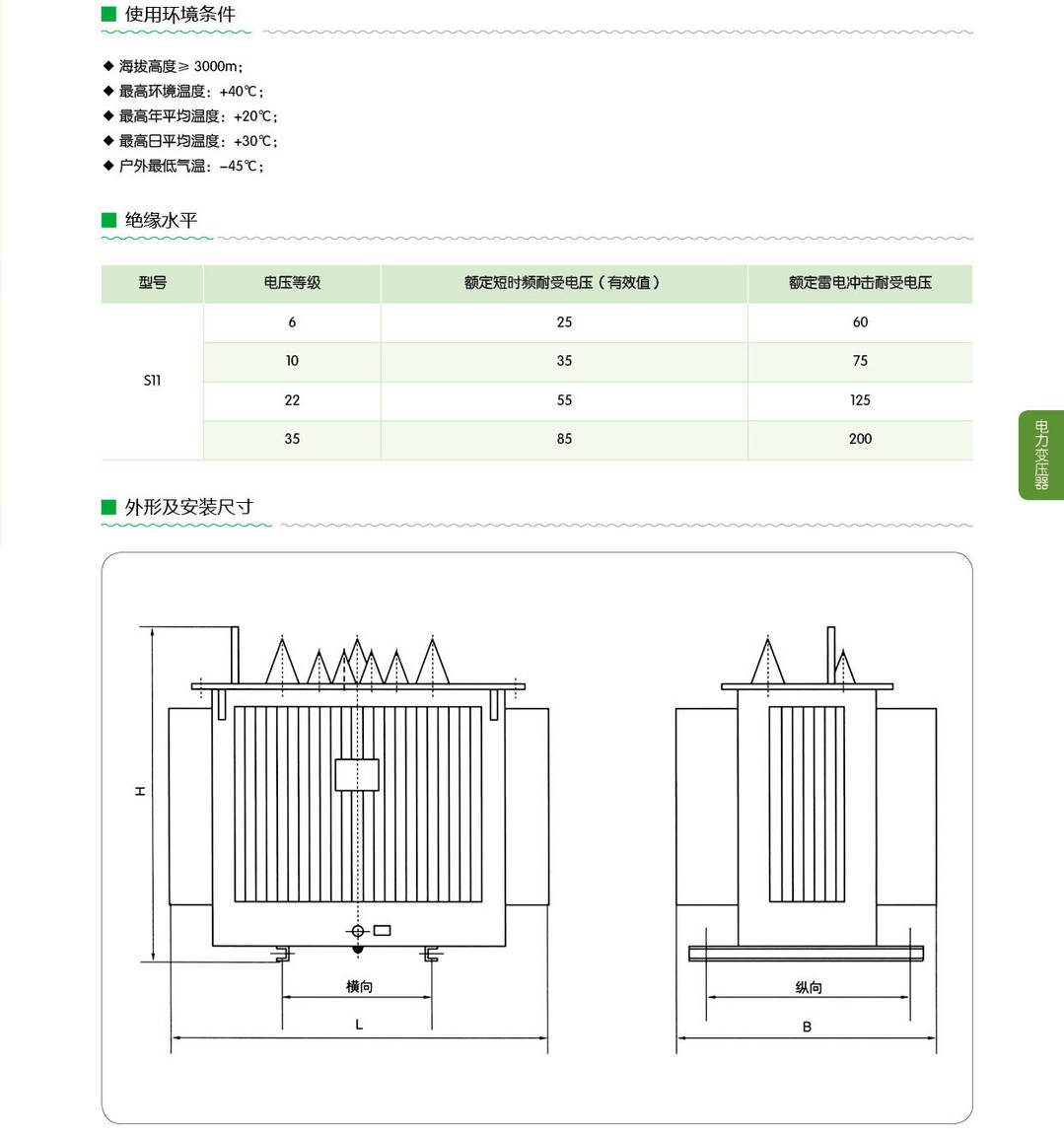

5. Conditions of normal use

6. The altitude does not exceed 1000m, indoor or outdoor

7. The maximum ambient temperature is +40°C, and the maximum daily average temperature is +30°C

8. The highest annual average temperature is +20°C and the lowest temperature is -25°C

9. According to the user’s requirements, the transformer can be provided to operate under special use conditions