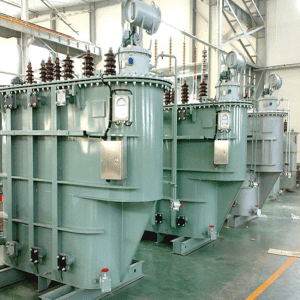

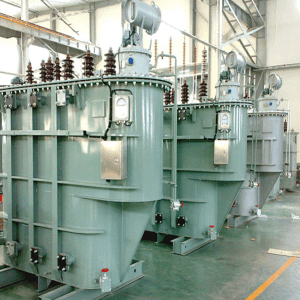

Product description

[S9-M series fully sealed oil-immersed transformer] is based on summarizing the design experience of S7 and S9 series transformer products, putting the increase of product functions, improving the product level and improving the reliability of the product in the first place, using new components, new materials, new structures and improving the local structure, improving the electrical strength, mechanical properties and heat dissipation capacity of the product, using corrugated oil tank and fully sealed structure to ensure that the transformer oil and air are completely isolated, prolong the service life of the transformer, and reduce the maintenance workload of the transformer. Sales Hotline: 13508930968

Features:

A Transformer oil tank: the use of corrugated oil tank, fully sealed structure, corrugated plate wall has two functions of heat dissipation and expansion, corrugated plate wall with the change of temperature, the size of the load, the height of the transformer oil temperature in the oil tank and automatic expansion, the expansion function of the corrugated plate wall is greater than 10,000 times to ensure that the transformer oil and air are completely isolated, and there is no need to maintain during the life of the transformer. B safety protection: the fully sealed transformers are equipped with pressure release valves, which expands the application range of pressure relief valves and increases the effective safety protection of the products.

C Tap-changer: The new double-sealed vertical switch is adopted to improve the sealing performance of the switch.

D Sturdy parts in the box: a new type of relaxation is adopted to ensure that the transformer body is tightened and not loosened during transportation.

E The body is connected with the box cover: the hanging plate belt structure is used to ensure that the transformer body can land and not top the box cover.

F Before installation, unscrew the top nut of the air plug and check the oil level, if the oil level is lower than 50mm, the transformer oil of the same oil number must be filled to the top 30mm.

4. The main product performance parameters of S9 10kv double winding series:

| Model number |

Rated capacity KVA |

Rated voltage KV |

Connection Group |

No-load loss W |

Load loss W |

No-load current % |

Impedance voltage % |

Weight Kg | Trajectory mm |

Dimensions mm | ||||

| High Voltage KV |

High-voltage tap range |

Low pressure KV |

Oil weight Kg |

The body weighs kg |

Total weight kg |

Length× width × height | ||||||||

| S9-30/10 | 30 | 6 6.3 10 |

±5% | 0.4 | Y.yn0 | 130 | 600 | 2.1 | 4 | 70 | 140 | 280 | 400×400 | 966×725×1145 |

| S9-50/10 | 50 | 170 | 870 | 2.0 | 80 | 205 | 375 | 400×400 | 1002×748×1145 | |||||

| S9-63/10 | 63 | 200 | 1040 | 1.9 | 90 | 235 | 430 | 400×400 | 1025×770×1170 | |||||

| S9-80/10 | 80 | 250 | 1250 | 1.8 | 100 | 280 | 490 | 400×400 | 1080×730×1230 | |||||

| S9-100/10 | 100 | 290 | 1500 | 1.6 | 110 | 325 | 560 | 400×400 | 1082×900×1270 | |||||

| S9-125/10 | 125 | 340 | 1800 | 1.5 | 125 | 375 | 650 | 400×400 | 1142×1070×1280 | |||||

| S9-160/10 | 160 | 400 | 2200 | 1.4 | 140 | 450 | 760 | 550×550 | 1204×840×1704 | |||||

| S9-200/10 | 200 | 480 | 2600 | 1.3 | 165 | 525 | 875 | 550×550 | 1357×885×1442 | |||||

| S9-250/10 | 250 | 560 | 3050 | 1.2 | 190 | 625 | 1040 | 500×580 | 1400×975×1573 | |||||

| S9-315/10 | 315 | 670 | 3650 | 1.1 | 220 | 745 | 1225 | 660×650 | 1442×1095×1697 | |||||

| S9-400/10 | 400 | 800 | 4300 | 1.0 | 275 | 905 | 1465 | 660×650 | 1432×1180×1692 | |||||

| S9-500/10 | 500 | 960 | 5150 | 1.0 | 305 | 1050 | 1715 | 660×650 | 1588×1006×1841 | |||||

| S9-630/10 | 630 | 1200 | 6200 | 0.9 | 4.5 | 395 | 1280 | 2110 | 600×860 | 1875×1130×1802 | ||||

| S9-800/10 | 800 | 1400 | 7500 | 0.8 | 455 | 1510 | 2575 | 820×820 | 2120×1155×2343 | |||||

| S9-1000/10 | 1000 | 1700 | 10300 | 0.7 | 525 | 1675 | 2860 | 820×820 | 2040×1480×1965 | |||||

| S9-1250/10 | 1250 | 1950 | 12000 | 0.6 | 585 | 1955 | 3330 | 820×820 | 2095×1570×1990 | |||||

| S9-1600/10 | 1600 | 2400 | 14500 | 0.6 | 670 | 2390 | 3970 | 820×900 | 2130×1580×2045 | |||||

5. Conditions of use

1 Maximum ambient temperature: +40°

2 Minimum ambient temperature: -25°

3 Altitude: < 1000 meters

4 Maximum monthly average relative humidity: 90%【20°】

5. Installation site: Installed in a place where there is no fire, explosion hazard, serious pollution, chemical corrosion and severe vibration, indoor or outdoor. Sales Hotline: 13508930968