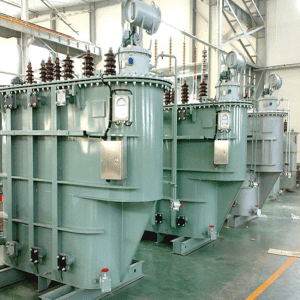

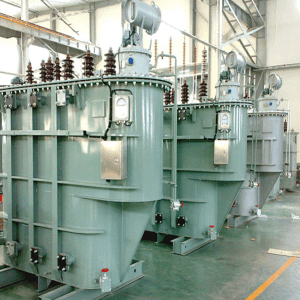

Product description

Oil-immersed transformer refers to the application of fluid/oil for the cooling medium, and one of the important meanings of the casing is to store and discharge the special oil for the transformer. It is widely used in the power supply system of factories, mining enterprises and civil buildings, and the price is more affordable than that of dry transformer.

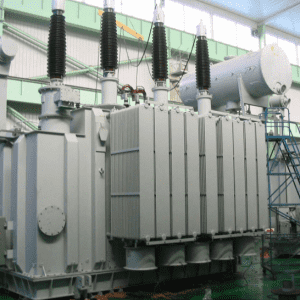

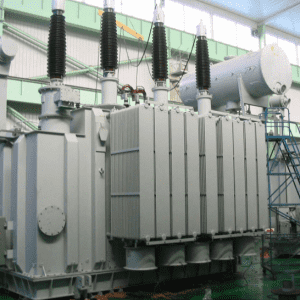

In terms of structural classification, oil-immersed transformers are mainly composed of iron cores, oil tanks, winding resistors, oil pillows, tap-changers, insulating pipes and gas relays.

Oil-immersed transformers are divided into three-phase transformers and single-phase transformers according to the number of phases, which are basically three-phase oil-immersed transformers, because the larger short-circuit capacity of three-phase is 2500kVA, while single-phase refers to 833kVA; Therefore, it is not recommended to use a single-phase transformer.

Key features:

Low loss, low noise

Low local release

Strong short-circuit resistance

Oil leakage avoidance technology

Efficient refrigeration technology

The site is free of hanging covers, and it is maintenance-free

Energy saving, environmental protection

What are the important components of an oil-immersed transformer?

1. Iron core: The iron core is the core of the transformer magnetic circuit, and the core structure is divided into two types of transformers: heart structure and shell structure. Cardiotype transformer: The primary and secondary windings of the cardio transformer are sleeved on the two core pillars of the core. The structure is compact, and the power transformers are all centered on the structure. Shell transformer: The core of the shell transformer surrounds the upper and lower sides of the resistance. The manufacturing is complicated, and small dry-type transformers are mostly used.

2. Resistance winding (coil): Resistance winding is the circuit part of the transformer, which is wound with insulated copper wire or aluminum wire. The role of winding resistor is to act as a carrier of electric current, generating magnetic flux and inducing electromotive force. It is also divided into high-voltage winding, low-voltage winding, same-boat winding and overlapping winding

3. Accessories: The accessories of the power transformer include oil tank, oil pillow, tap changer, safety air duct, insulating pipe, etc. Its role is to ensure the safe and reliable operation of the transformer.

(1) The oil tank, that is, the oil-immersed transformer shell, is used to dissipate heat and protect the body of the transformer (the body of the transformer is placed in the oil tank), and there is transformer oil for insulation in the tank.

(2) Oil conservator (oil pillow): installed on the fuel tank to block the inside and outside of the oil tank.

(3) Safety airway (explosion-proof pipe): Install it on the top cover of the fuel tank to maintain the equipment and avoid destroying the fuel tank when there is an abnormality. When the transformer fails and a large amount of gas is generated, the pressure in the fuel tank increases, and the gas and oil will break the explosion-proof film and spray out, preventing the fuel tank from bursting.

(4) Gas relay (gas solenoid valve): installed in the pipeline between the oil tank and the oil storage tank of the transformer, the key protection equipment.

(5) Tap changer: The switch is connected with different joints, which can change the number of turns of the original winding to achieve the purpose of adjusting the voltage. Tap-changers are divided into on-load tap-changers and non-load-regulated tap-changers.

(6) Insulating pipe: The function of installing on the fuel tank cover of the transformer is to lead the end of the coil wire out of the oil tank and insulate the wire from the oil tank. Porcelain insulating pipe is selected for voltage less than 1KV, gas or oil-filled sleeve is selected for voltage of 10-35KV, and capacitive sleeve is selected for voltage higher than 110KV.

(7) Transformer oil: strengthen insulation and heat dissipation. It is required to have strong material strength and low viscosity, strong ignition point and low condensation point, and do not contain impurities such as acid, alkali, dust and moisture.

(8) Temperature measuring device: detect the oil level temperature of the transformer. Mercury thermometers are used for small oil-immersed transformers, and pressure thermometers are used for larger transformers.