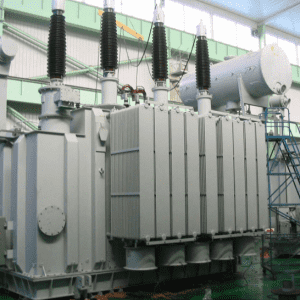

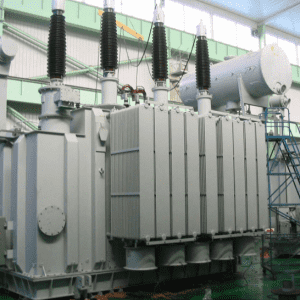

Product description

The big difference between 80KVA oil-immersed transformer and other types of transformers is the no-load loss of the transformer, and the no-load loss of the transformer depends on the magnetic permeability of the core material of the transformer. The core of the 80KVA oil-immersed transformer is made of isotropic soft magnetic permeable material-amorphous alloy, which has low magnetizing power, high resistivity and low eddy current loss. The no-load loss and no-load current of the transformer core made of amorphous alloy material are very low, of which the no-load loss is about 75% lower than that of S9 transformer, and about 65% lower than that of S11 transformer, which greatly reduces the operating cost and the energy-saving effect is very significant.

Conditions of use of 80KVA oil-immersed transformer:

1. Altitude of use: H<1000m

2. High ambient temperature: +40

3. High monthly average temperature: +35

4. High annual average temperature: +20

5. Low ambient temperature: -25

6, Large daily temperature difference: 25

7. Relative humidity: high monthly average: 90 (20)

High daily average: 95 (20)

8. Earthquake resistance: ground horizontal acceleration 0.2g;

Ground vertical acceleration 0.1g;

9. The inclination of the installation site: not more than 3°

80KVA oil-immersed transformer features:

●This series of products has the characteristics of fully enclosed, maintenance-free, core-free, low noise and low loss.

●The no-load loss rate is about 20% lower than that of S9 series oil-immersed transformer;

●The iron core adopts the clamping method of steel strip and coated epoxy resin, which reduces the steel structure in the leakage magnetic field and never reduces the stray loss in the operation of the product.

●The coil part adopts the method of separating the voltage regulating coil and the main coil, which improves the mechanical strength of the coil, reduces the ampere-turn unbalance of the coil, and improves the anti-short circuit ability of the product.

●The pressing plate of the insulating part of the body adopts electrical lamination technology.

●The bell type fuel tank adopts a corrugated fuel tank formed by steel plate, which reduces the weight and increases the mechanical strength and heat dissipation effect.

●The upper and lower fuel saving tanks adopt welding wire structure, which improves the sealing performance of the product, reduces the noise and avoids leakage.

The 80KVA oil-immersed transformer core has high dielectric strength, the transformer core and coil are vacuum dried, and the transformer is assembled with full vacuum oil injection process, and the insulation level of the product has reached a new level. The 80KVA oil-immersed transformer has strong short-circuit resistance, and it is difficult to fix the core and coil in a conventional way because the amorphous alloy core cannot withstand large pressures. Our company has effectively ensured the anti-short-circuit ability of the products by adopting special structural design and process methods. Among them, each coil of the amorphous alloy double-change ratio fully sealed oil-immersed transformer designed and manufactured by our company has passed up to 6 short-circuit tests, which proves that the product has a strong short-circuit resistance.