Product description

Product Overview

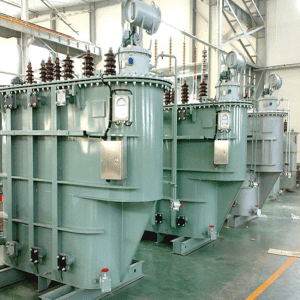

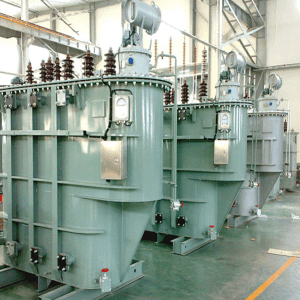

The 80KVA dry-type transformer developed and produced by the company has the advantages of low loss and low noise, which can achieve good energy-saving effect and reduce pollution. Compared with ordinary oil-immersed transformers, the 80KVA dry-type transformer cancels the oil conservator, and the change of oil volume is automatically adjusted and compensated by the elasticity of the corrugated sheet of the corrugated oil tank, and the transformer is isolated from the air to prevent and slow down the deterioration of oil and insulation aging, enhance the reliability of operation, and operate normally without maintenance.

■ Conditions of use

Ambient temperature: +40°C

Ambient temperature: -25°C

Altitude:<1000m

Monthly Average Relative Humidity: 90% ( 20°C )

Installation site: Installed in a place where there is no fire, explosion hazard, serious pollution, chemical corrosion and severe vibration, indoor or outdoor.

Features:

The core of the 80KVA dry-type transformer is made of imported cold-rolled silicon steel sheets, which greatly reduces the no-load loss and no-load current, and binds the core to ensure the compactness of the core and reduce noise.

The high and low voltage windings are wound with oxygen-free copper, the low-voltage windings are 500kVA and below with a double-layer cylindrical structure, 630kVA and above are double-helix or quadruple-helix structures, and the high-voltage windings are made with a multi-layer cylindrical structure.

Dyn11 is used in the transformer coupling group to reduce the impact of harmonics on the power grid and improve the quality of power supply.

The transformer is a fully sealed structure, which prolongs the service life, no hanging heart, and no maintenance.

The measured noise value is lower than the standard.

After normal transportation, the S11-M-500KVA oil-immersed transformer can be installed without hanging heart inspection, and the acceptance project test can be carried out, and it can be put into operation after passing the inspection.

■Execution standards

GB 1094. 1 Power transformer

GB/T 15164 Load Guidelines for Oil-Immersed Power Transformers

GB/T 6451 Load Guidelines for Three-phase Oil-Immersed Power Transformers GB 2536 Transformer Oil

JB/T 3837 Methods for compiling models of transformer products JB/T 501 Test guidelines for power transformers

GB 1094.3 Air Gap for External Insulation of Transformer Insulation Level and Insulation Test DL/T572 Transformer Operation Regulations

The above standards are subject to the publication; Other requirements for equipment should be subject to the corresponding national or professional standards.

80KVA dry-type transformer features:

1. The coil is wound with copper wire or foil, reinforced with glass fiber, epoxy resin is poured without filler, vacuum drying, degassing and dehumidification, high mechanical strength, short circuit resistance, and strong impact resistance.

2. The head end of the high-voltage winding and the middle tap tap are embedded with copper inserts, which has good rigidity, easy to adjust gears, and is beautiful and neat.

3. The iron core is made of high-quality grain-oriented cold-rolled silicon steel sheets, and the 45-degree full-oblique multi-step joints are stacked. The surface is covered with resin insulating coating, which is moisture-resistant, rust-proof, and noise-resistant.

4. The elastic parts are clamped between the core, the clamp and the coil to make the coil in a stable compression state to reduce noise.

5. The transformer is designed according to self-cooling, and a longitudinal ventilation channel is reserved inside the cylinder wall of the high-voltage (low-voltage) coil for overall casting, which can be equipped with a forced air cooling device (cooling fan), and the output capacity can be increased by 50% after the forced air cooling device is adopted.

6. Equipped with a thermostat, a platinum resistor (Pt100) is placed in the embedded hole at the top of the low-voltage coil. In order to monitor the temperature rise of the transformer winding, automatically start and stop the cooling fan, and have the functions of fault alarm, over-temperature alarm and over-temperature tripping, it provides reliable overload protection device for the 80KVA dry-type transformer, so as to improve the safety of the operation of the 80KVA dry-type transformer.

The 80KVA dry-type transformer is safe, flame retardant, fireproof, pollution-free, and can be installed directly in the load center. Maintenance-free and easy to install. It has good moisture-proof performance and can be put into operation without pre-drying after being out of operation. Low loss, low partial discharge, low noise, forced air cooling, 120% rated load operation. It has a complete temperature protection control system to provide reliable guarantee for the safe operation of the transformer. The reliability index of the product has reached the domestic advanced level.