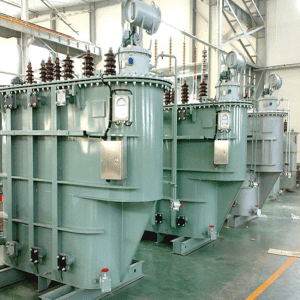

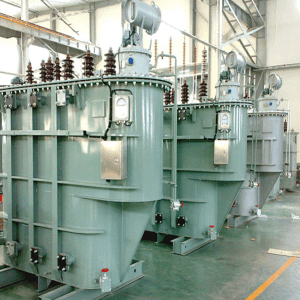

Product description

The 630KVA oil-immersed transformer implements the ** standard GB1094 “Power Transformer” and GB/T6451 “Technical Parameters and Requirements for Three-phase Oil-immersed Power Transformer”, and the 630KVA oil-immersed transformer adopts coiled core in the structure and is supported by high-stability coils, which improves the reliability of product operation.

630KVA oil-immersed transformer product model

Good technical and economic performance: On the basis of S9 series, the no-load loss of S11 products is reduced by 30% on average, and the no-load current is 70-85% lower than that of S9.

Long service life: The transformer oil tank adopts a fully sealed structure, the oil tank and the tank edge can be bolted or welded, and the transformer oil is not in contact with the air to prolong the service life.

High operational reliability: The relevant parts of the fuel tank seal have been improved, the reliability has been increased, and the process level has been improved to ensure the reliability of the seal.

Small footprint: S11-M series power transformer oil tank adopts corrugated plate radiator, when the oil temperature changes, the corrugated plate thermal expansion and contraction can replace the role of the oil conservator, the corrugated plate oil tank has a beautiful appearance and a small footprint.

Normal conditions of use:

1. The altitude does not exceed 1000m, indoor or outdoor

2. **Ambient temperature +40°C**Daily average temperature +30°C

3. **Annual average temperature +20 °C** temperature -25 °C

4. According to user requirements, transformers can be provided to operate under special use conditions.

Performance characteristics:

a. In addition to the copper wire used for small capacity, the low-voltage winding of oil-immersed transformer generally adopts a cylindrical structure of copper foil winding and pumping; The high-voltage winding adopts a multi-layer cylindrical structure, so that the ampere-turn distribution of the winding is balanced, the magnetic flux leakage is small, the mechanical strength is high, and the short-circuit resistance is strong.

B. The core and winding have adopted fastening measures, and the fastening parts such as the height and low-voltage lead are equipped with self-locking locknuts, and the non-hanging structure is adopted, which can withstand the shock of transportation.

c. The coil and core are dried by vacuum, and the oil-immersed transformer oil is made by vacuum oil filtration and oil injection, so that the moisture inside the oil-immersed transformer is reduced to the highest level.

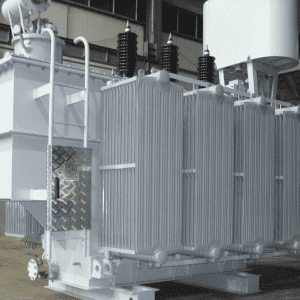

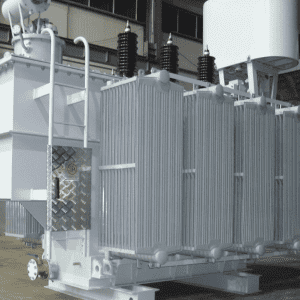

d. The oil tank adopts corrugated sheets, which has a breathing function to compensate for the volume change of oil caused by temperature changes, so the product does not have an oil storage cabinet, which obviously reduces the height of the oil-immersed transformer.

e. Because the corrugated sheet replaces the oil conservator, the transformer oil is isolated from the outside world, which effectively prevents the entry of oxygen and water from leading to the decline of insulation performance.

f. According to the above five performances, it ensures that the oil-immersed transformer does not need to change oil during normal operation, which greatly reduces the maintenance cost of the transformer and prolongs the service life of the transformer.

Structural characteristics of 630KVA oil-immersed transformer

1. Iron core: three-phase three-column inner and outer frame rolling structure, and the core column is a multi-step stepped circular section; After the core is rolled, the stress is removed by vacuum annealing, the groove bending clamp, the screw body is tensioned, and the surface of the core is coated with special glue to ensure that the core is not deformed and stainless steel.

2. Winding and body: The low-voltage winding is a four-layer or double-layer cylindrical (500KVA and below) or spiral (630KVA and above) winding with 1-6 wires, and the wires are drawn from oxygen-free copper. The interlayer insulation of the high and low voltage winding is rhombic dispensing paper, the axial oil channel of the high-voltage winding and the oil gap of the main air channel between the high and low voltage are the brace curtain structure, and the iron yoke insulation is integrated with the trapezoidal cushion block to make the body evenly compressed. The body adopts a new type of hanging plate positioning structure, longitudinal and horizontal positioning, to ensure that the body is stable and not displaced.

3. Fuel tank: corrugated oil tank, sealed structure, no oil leakage, maintenance-free.

630KVA oil-immersed transformer is suitable for power systems, industrial and mining enterprises, transportation, post and telecommunications departments, scientific research units, etc., to carry out dielectric strength tests under power frequency or DC high voltage for various high-voltage electrical equipment, electrical components, and insulating materials. The 630KVA oil-immersed transformer adopts a single-frame core iron core structure. The primary windings are wound around the core and the high-voltage windings are outside, and this coaxial arrangement reduces the leakage flux and thus increases the coupling between the windings.