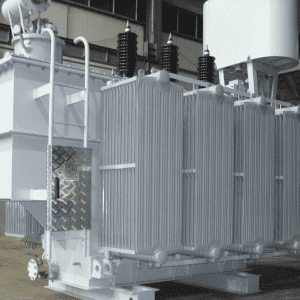

Product description

The 5000KVA dry-type transformer is safe, flame retardant, fireproof, pollution-free, and can be installed directly in the load center. Maintenance-free and easy to install. It has good moisture-proof performance and can be put into operation without pre-drying after being out of operation. The 5000KVA dry-type transformer has low loss, low partial discharge, low noise, and can be 120% under forced air cooling conditions. Rated load operation. It has a complete temperature protection control system to provide reliable guarantee for the safe operation of the transformer. The reliability index of 5000KVA dry-type transformer has reached the domestic advanced level.

The pouring coil of the 5000KVA dry-type transformer with short glass filament as the packing adopts the segmented garden barrel type, and the axial airway is provided inside the coil to improve the heat dissipation conditions. The scientific pouring molding process can ensure that the resin fully penetrates into the turns, layers and sections to ensure the electrical dielectric strength of the product and less local placement (≤5pc). How to prevent the cracking of the resin casting body, control the generation of residual air bubbles in the casting body, and reduce the partial discharge to a small limit has always been a major issue for dry transformation manufacturers at home and abroad, and it is the key manufacturing technology of resin casting dry-type transformers.

Through repeated production practices and frequent physical and chemical tests, the company has successfully solved this problem, so that the company’s thin insulating vacuum casting products with short glass filament as filler have their tensile strength increased to 170N/mm2 and bending strength increased to 220N/mm2 The mechanical properties of the resin cured body are improved overall. The uniqueness of the manufacturing technology of our SC(B)10 series resin cast thin insulation dry transformation products is as follows:

1. The resin thickness of the encapsulation layer is thinned, and the heat dissipation capacity of the coil is enhanced.

2. The coil is strengthened by glass felt, which enhances the mechanical strength of the coil, improves the ability of the product to resist sudden short circuit, and successfully solves the problem of cracking of the pouring body.

3. The coil adopts a special process, which greatly reduces the partial discharge inside the coil and improves the electrical strength of the coil.

4. The low-voltage coil adopts a foil structure, which reduces the magnetic flux leakage at the end and improves the ability of the product to resist sudden short circuit.

5000KVA dry-type transformer application range:

Suitable for AC 50Hz/60Hz; It is widely used in industrial and mining enterprises, production workshops, power plants, airports, high-rise buildings, subways and other places with high safety requirements, precision machine tools, machining centers, printing equipment, automatic control equipment, UPS power supplies, all kinds of machinery, etc. It has the functions of transforming voltage, isolating impurities in the power grid, converting wiring methods, supplying lighting electrical facilities, numerical control systems, power supplies, and rectifying power supplies.

5000KVA dry-type transformer features:

Technical characteristics: high isolation; N-G performance is good; High common-mode interference rejection; Convert △ to Y or Y to △; The voltage tap is easy to convert, etc.

Core material: imported new high-quality cold-rolled silicon high magnetic flux steel sheet (B value 12000-16000); Column core, reasonable structure, good performance, high efficiency, low noise.

Winding material: high-strength heat-resistant enameled wire is selected, with good electrical conductivity and heat resistance, and certain corrosion resistance. The winding is wound by the whole process of debirth.

Production process: the introduction of advanced vacuum impregnation equipment in the industry, secondary vacuum impregnation drying, greatly enhance the mechanical strength of the transformer, improve the insulation performance, and prolong the service life.

Perfect configuration: transformers are equipped with chassis, parameter display interface, and indicator lights; Equipped with automatic temperature control and heat dissipation system; Peripherals such as top lifting rings and bottom rollers can be installed; And can be completely customized according to the special requirements of users.