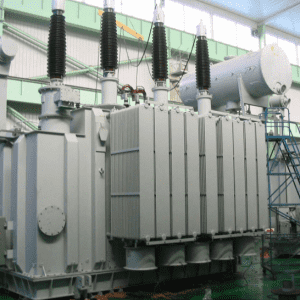

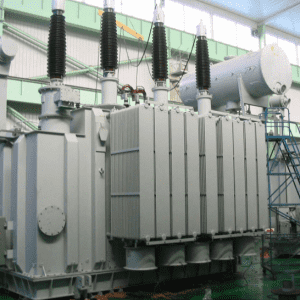

Product description

In the 10KV and 50HZ transmission and distribution system, the 400KVA oil-immersed transformer can be widely used in high-rise buildings, commercial centers, subways, airports, stations, industrial and mining enterprises, drilling platforms, oil production platforms, especially suitable for flammable, explosive and other places with high fire protection requirements and harsh environment. The 400KVA oil-immersed transformer can also be used for residential areas, commercial streets, industrial and mining enterprises, and rural power and lighting. The 400KVA oil-immersed transformer is a new type of energy-saving product with the characteristics of low loss, low noise, strong anti-short circuit ability and high operation reliability. The product has a clean and beautiful appearance and superior technical performance. Compared with S9 series transformers, the no-load loss of 400KVA oil-immersed transformer is reduced by 30%, the no-load current is reduced by 70-85%, the average temperature rise is reduced by 10K, and the operating noise of the product is reduced by 2-4 decibels on average. More economical and reliable operation.

The 400KVA oil-immersed transformer is mainly composed of iron core, winding, oil tank, oil pillow, insulating sleeve, tap changer and gas relay.

1. Iron core

The core is the magnetic circuit part of the 400KVA oil-immersed transformer. During operation, hysteresis loss and eddy current loss are generated and heat is generated. In order to reduce heat loss and reduce volume and weight, the core is composed of cold-rolled grain-oriented silicon steel sheet with a high magnetic permeability of less than 0.35mm. According to the arrangement of the windings in the core, there are iron core type and iron shell type. In the large-capacity 400KVA oil-immersed transformer, in order to make the heat emitted by the core loss be fully taken away by the insulating oil during circulation, so as to achieve a good cooling effect, a cooling oil channel is often provided in the core.

2. Winding

The windings and iron core are the core components of the 35KV oil-immersed power transformer. Since there is resistance in the winding itself or contact resistance at the joint, it is determined by Joule’s law

It is known that heat is generated. Therefore, the winding cannot pass a current higher than the rated current for a long time. In addition, when the short-circuit current is passed, a large electromagnetic force will be generated on the windings and the 35KV oil-immersed power transformer will be damaged. There are two types of basic windings: concentric and overlapping.

The main faults of 400KVA oil-immersed transformer winding are inter-turn short circuit and short circuit to the shell. The inter-turn short circuit is mainly caused by the aging of the insulation, or due to the overload of the 400KVA oil-immersed transformer and the mechanical damage to the insulation during the traversal short circuit. The oil level in the 400KVA oil-immersed transformer drops, causing the winding to expose the oil surface, and the inter-turn short circuit can also occur; In addition, when there is a crossing short circuit, the winding is deformed due to the action of overcurrent, and the insulation is mechanically damaged, which will also cause an inter-turn short circuit. In the case of turn-to-turn shorts, the current in the short-circuit winding may exceed the rated value, but the current in the winding as a whole may not exceed the rated value. In this case, the gas protection action, and when the situation is serious, the differential protection device will also act. Short circuits to the enclosure are also caused by aging insulation or oil moisture, drop in oil level, or due to lightning and operating overvoltage. In addition, in the event of a pass-through short circuit, the windings are deformed due to overcurrent, and a short circuit to the housing may occur. When the shell is short-circuited, it is generally the action of the gas protection device and the grounding protection action.

3. Fuel tank

The body (winding and core) of the 400KVA oil-immersed transformer is installed in an oil tank filled with 35KV oil-immersed power transformer oil, and the oil tank is welded with steel plates. The oil tank of the 400KVA oil-immersed transformer is composed of a box shell and a box cover, and the body of the 400KVA oil-immersed transformer is placed in the box shell, and the box cover can be lifted out of the body for maintenance.

Peculiarity:

1. The product has the advantages of fully enclosed, maintenance-free, core-free, low noise and low loss.

2. The no-load loss rate is reduced by about 20% compared with the S9 series oil-immersed transformer;

3. The iron core adopts the clamping method of steel belt and coated epoxy resin, so as to reduce the stray loss in the operation of the product.

4. The coil part adopts the method of separating the voltage regulating coil and the main coil, which improves the mechanical strength of the coil, reduces the ampere-turn imbalance of the coil, and improves the anti-short circuit ability of the product.

5. The pressing plate of the insulating part of the body adopts electrical lamination technology.

6. The bell type fuel tank adopts a corrugated fuel tank formed by steel plate. The upper and lower fuel saving tanks adopt welding wire structure, which improves the sealing performance of the product, while reducing noise and avoiding leakage.

Terms of use

Altitude:<1000m

Ambient temperature: +40°C-25°C

Relative humidity of air≤90%(+25°C)

Device type: Outdoor type

Installation site: no corrosive gas, no obvious dirt and other areas

Enforce the standard

GB1094.1-2~1996

GB1094.3.5-2003

GB/T6451-1999

When the 400KVA oil-immersed transformer has a large number of primary or secondary loads, it is advisable to install two or more 35KV oil-immersed power transformers, and when any of the 400KVA oil-immersed transformers are disconnected, the capacity of the remaining 400KVA oil-immersed transformers can meet the electricity consumption of primary and secondary loads. The primary and secondary loads should be concentrated as much as possible and should not be too dispersed.