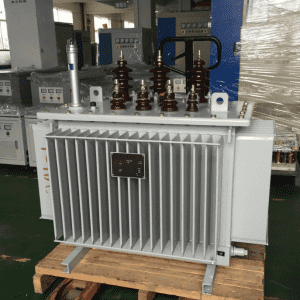

Product description

40000KVA oil-immersed transformer is a large-capacity transformer, which is widely used in power system, industrial production and scientific research experiments. The following will introduce the features, advantages, application scenarios and maintenance of 40000KVA oil-immersed transformer in detail.

1. Features

Large capacity: 40000KVA oil-immersed transformer has a large capacity, which can meet the power demand of high load and high power, and is suitable for step-up and step-down substations in the power system.

Oil-immersed heat dissipation: The transformer adopts oil-immersed heat dissipation, using transformer oil as the cooling medium to transfer heat to the radiator or oil tank wall, and then dissipate the heat through the radiator or natural cooling.

Good insulation performance: The oil-immersed transformer adopts advanced insulation materials and advanced insulation structure, which can operate normally in harsh environments such as high voltage and ultra-high voltage to ensure the safety and stability of the power system.

Convenient maintenance: The oil-immersed transformer has a simple and compact structure, which is relatively convenient to maintain, and generally only needs to be checked and replaced regularly.

2. Advantages

High efficiency: The 40000KVA oil-immersed transformer adopts advanced design and manufacturing technology, which can achieve high-efficiency energy conversion and reduce energy loss.

High reliability: The transformer has high reliability and stability, and can operate normally under various complex environmental and climatic conditions, reducing the failure rate and maintenance costs.

Strong adaptability: 40000KVA oil-immersed transformer is suitable for a variety of different application scenarios, such as power system, industrial production, scientific research experiments, etc., and can meet the needs of different fields.

3. Application scenarios

40000KVA oil-immersed transformer is widely used in the following scenarios:

Power system: used in step-up and step-down substations to meet the power needs of high-voltage, ultra-high-voltage and low-voltage in the power system.

Industrial production: It is used for various industrial production lines and equipment to provide stable and reliable power supply.

Scientific research experiments: used in various scientific research experiments and testing equipment, providing high-precision voltage and current.

Fourth, maintenance

In order to ensure the normal operation and service life of the 40000KVA oil-immersed transformer, regular maintenance is required. The specific maintenance content includes the following aspects:

Regular inspection: Regularly inspect the appearance, fasteners and seals of the transformer to ensure that there are no abnormal phenomena and damage. At the same time, it is necessary to check whether the grounding and safety protection devices of the transformer are working normally.

Oil replacement and treatment: Regularly check the oil level, oil temperature and oil quality of the transformer, and refuel or change the oil as needed. When changing the oil, use qualified transformer oil and ensure that the cleanliness and purity of the oil meet the requirements. At the same time, it is necessary to carry out refueling or oil change operations in accordance with the prescribed procedures and steps to avoid unnecessary damage to the transformer.

Clean the radiator: The radiator is one of the important components of the transformer and needs to be cleaned and maintained regularly. It is necessary to regularly check the appearance and internal condition of the radiator, remove the dirt and debris on the radiator, and ensure that the ventilation and heat dissipation effect of the radiator is good. At the same time, check the fasteners and seals of the radiator to ensure that there are no abnormalities and damage.

Check the electrical connections: The electrical connection part of the transformer needs to be checked and maintained regularly. Check whether the cables, wires and plugs are tightened and intact, and there is no loosening and poor contact. At the same time, it is necessary to regularly clean up the dust and dirt on the electrical components to prevent the occurrence of electrical failures.

Recording and statistics: When carrying out the maintenance and maintenance of transformers, it is necessary to do a good job of recording and statistics. It is necessary to record the time, content, problems found and treatment of maintenance and maintenance, so as to find and deal with the problems and hidden dangers of the equipment in time. At the same time, through statistics and analysis of recorded data, the operation status and service life of the equipment can be understood, and the basis and suggestions for the maintenance and replacement of the equipment can be provided.