Product description

Product Overview

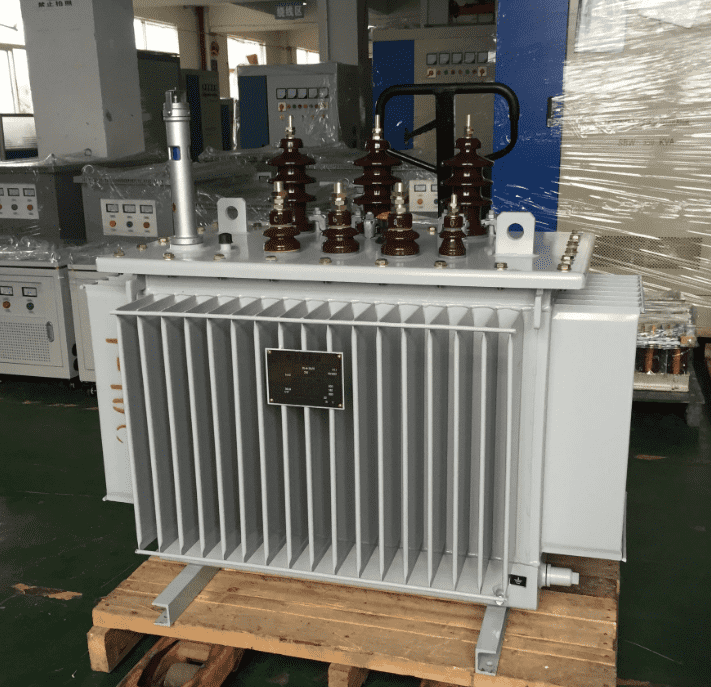

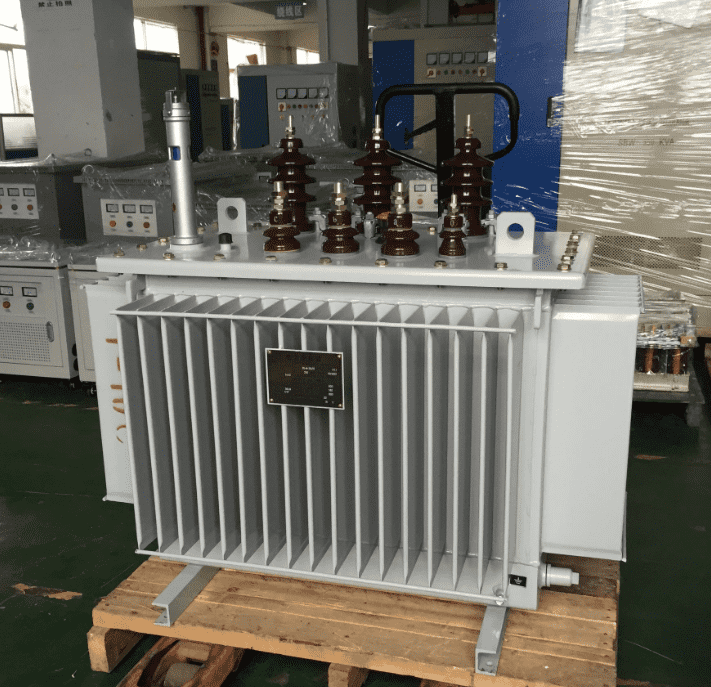

The 35kV class S11, SZ11 and SFZ11 series products meet the IEC60076 of the International Electrotechnical Commission and the national standards of the People’s Republic of China GB1094 “Power Transformer” and GB/T6451 “Technical Parameters and Requirements for Three-phase Oil-immersed Power Transformers”. The on-load voltage regulation range of this product is 35±2*2.5%kV, 38.5±2*2.5%kV, 35±3*2.5%kV, 38.5±3*2.5%kV, and the voltage can be adjusted manually, electrically or automatically within the voltage regulation range with the help of the on-load voltage regulating switch on the primary side to ensure the stability of the output voltage. The transformer above 35kV 6300kVA adopts a folding plate oil tank, which greatly strengthens the mechanical strength of the fuel tank, reduces the weld, and improves the appearance quality of the transformer. This product is a replacement product and has good operating economic benefits.

As the most widely used power facilities, power transformers have a wide range of types, which are of great significance for energy conservation and emission reduction. S11 fully sealed oil-immersed power transformer is the main selection product of power distribution equipment, and the energy saving effect is remarkable.

The meaning of the performance code of distribution transformers in China is: above the S7 type, the no-load loss is reduced by about 10%, and the code “7” is added to the number with “1”. From the S7 type to the S9 type, the load loss is reduced more, with an average of 25%, and later, due to the lack of breakthrough new materials, new technologies and new processes, it is more difficult to reduce the load loss of the distribution transformer, so the performance level code is usually based on the reduction of no-load loss. Taking 400kVA products as an example, the no-load loss of the S7 type is 920W, and the no-load loss of the S11 type is 570W, a decrease of 38%.

At present, the mainstream distribution transformer generally chooses S11 type laminated core power transformer. Adopting the full oil-filled sealed type, no oil conservator, corrugated sheet box structure, the transformer due to the change of temperature and load caused by the change of oil temperature and volume, completely regulated by the corrugated oil tank, its no-load loss is reduced by 25% compared with S9, the lightning impact resistance and short circuit resistance is strong, the energy-saving effect is obvious, and the appearance size of the transformer is reduced. The S11 transformer is produced with high permeability oriented silicon steel sheet with a thickness of 0.27-0.30mm and a unit iron loss of 1w/kg, while the new S9 type is an ordinary silicon steel sheet with a thickness of 0.30-0.35mm and a unit iron loss of 1.20-1.55w/kg.

The S11 distribution transformer produced by our company is all made of 30P series high magnetic conductivity oriented silicon steel produced by Shanghai Baosteel, using foil winding coil and new insulating materials and processes, the product is high temperature resistance, impact resistance, and fully sealed structure design to ensure the stability of transformer oil quality and extend the maintenance cycle.

Long service life and maintenance-free operation. The fully sealed transformer cover and the edge of the box are bolted or welded to isolate the contact between oil and air, and the insulation will not be damp, which greatly reduces the aging rate of insulation and improves the service life. The design is compact and the operating noise is low. Due to the use of new materials and new processes, noise is reduced, there is no oil conservator, and the height is lower than similar products. There is no need to change the oil during the normal life cycle, which improves the safety and reliability of the operation on the network. The corrugated fuel tank is small in size and beautiful in appearance. The oil tank of S11 power transformer adopts corrugated sheet type heat dissipation, and when the oil temperature changes, the change of oil volume is adjusted and compensated by the elastic expansion and contraction of the corrugated sheet. No core and oil testing. When the transformer is encapsulated, the vacuum filtration oil injection process is used to completely remove the moisture in the transformer oil. After sealing, the inside of the transformer is not in contact with air, which effectively prevents oxygen and moisture from entering the transformer and causing the insulation performance to deteriorate.

GB1094.1.2.3-2007

GB/T6451-2009 Technical parameters and requirements for three-phase oil-immersed power transformers.

GB/T10237-1988

JB/T3837-1998

15. Insulation level:

(1) The power frequency withstand voltage of 10kV products is 35kV, and the lightning impulse voltage is 75kV

(2) The power frequency withstand voltage of 20kV products is 50kV, and the lightning impulse voltage is 125kV

(3) The power frequency withstand voltage of 35kV products is 70kV, and the lightning impulse voltage is 170kV

Main technical parameters of 10kV S11-M fully sealed oil-immersed power transformer

The main technical parameters of S11-M fully sealed oil-immersed power transformer

It is widely used in mechanical supporting, transportation, post and telecommunications, military, railway, import and export equipment, scientific research and culture and other fields of large-scale mechanical and electrical equipment, metal processing equipment, production lines, construction engineering equipment, elevators, medical equipment, embroidery and textile equipment, air conditioning, radio and television and household appliances, lighting and other places that need to be transformed.

Before leaving the factory, each product is fully inspected in strict accordance with the national standard to ensure that the factory pass rate is 100%

— manufacturers promise: all products are guaranteed for one year! If it fails within one year of normal use, it can be replaced free of charge! (Except for special customer requests)

Runsheng Transformer Co., Ltd. is a comprehensive power supply company integrating scientific research, production, sales, and product maintenance. The company has strong technical development force and first-class testing equipment, the company continues to strengthen the control of raw material quality and process to ensure the stability of product quality. Since its establishment, the company has been engaged in the production of: transformers, voltage regulators, voltage regulators, etc., more than 10 series, more than 100 kinds of products, products are exported to North America, Western Europe, the Middle East, North Africa and other more than 50 countries and regions, has been the majority of users of the praise.

When purchasing a product, the user should be clear about the following points:

1. The basic model, specification, capacity and quantity of transformer;

2. The primary and secondary voltage of the transformer, as well as the wiring method of the transformer:

3. Capacity allocation of equipment carried by transformer;

4. The shape and installation dimensions are for reference only, if the required size needs to be changed, it must be explained at the time of ordering.

After-sales guarantee:

1. The company produces various types of transformers, voltage regulators and voltage regulators, which can be customized according to customer requirements, sizes and specifications.

2. The quality assurance period of dry-type transformers, voltage regulators, voltage regulators and products produced by the company is three years.

3. If there is any product quality problem during the quality assurance period, our company is responsible for free repair or replacement.

4. The company has opened a national free 24-hour service hotline and divided into 24 hours, 48 hours, and within the time agreed with the user according to the user’s requirements.

5. Due to the power outage caused by product accidents, our company promises to arrive at the scene within 24 hours (48 hours in remote areas) in developed transportation areas to ensure that it is completed in the shortest possible time.