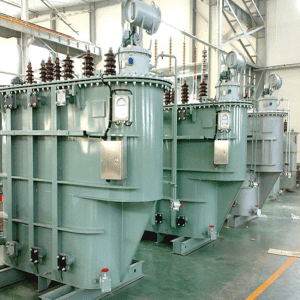

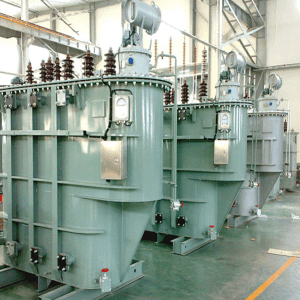

Product description

The 315KVA oil-immersed transformer is one of the important equipment in the power supply system of industrial and mining enterprises and civil buildings, which reduces the network voltage of 10 (6) kV or 80kV to 230/400V for users Bus voltage. The 315KVA oil-immersed transformer is suitable for AC 50 (60) Hz, three-phase larger rated capacity of 2500kVA (single-phase larger rated capacity of 833kVA, single-phase 35KV oil-immersed power transformer is generally not recommended), can be used indoors (outdoor) with a capacity of 315kVA When it is below, it can be installed on the pole, the ambient temperature is not higher than 40 °C, not lower than -25 °C, the higher daily average temperature is 30 °C, the higher annual average temperature is 20 °C, the relative humidity is not more than 90% (the ambient temperature is 25 °C), and the altitude is not more than 1000m. If it is inconsistent with the above conditions of use, it shall be adjusted according to the relevant provisions of GB6450-86.

The 315KVA oil-immersed transformer is mainly composed of iron core, winding, oil tank, oil pillow, insulating sleeve, tap changer and gas relay.

1. Iron core

The iron core is the magnetic circuit part of the 80KV oil-immersed power transformer. During operation, hysteresis loss and eddy current loss are generated and heat is generated. In order to reduce heat loss and reduce volume and weight, the core is composed of cold-rolled grain-oriented silicon steel sheet with a high magnetic permeability of less than 0.35mm. According to the arrangement of the windings in the core, there are iron core type and iron shell type.

In the large-capacity 35KV oil-immersed power transformer, in order to make the heat emitted by the loss of the iron core can be fully taken away by the insulating oil during circulation, so as to achieve a good cooling effect, a cooling oil channel is often provided in the iron core.

2. Winding

The windings and iron core are the core components of the 35KV oil-immersed power transformer. Since there is resistance in the winding itself or contact resistance at the joint, it is determined by Joule’s law

It is known that heat is generated. Therefore, the winding cannot pass a current higher than the rated current for a long time. In addition, when the short-circuit current is passed, a large electromagnetic force will be generated on the windings and the 35KV oil-immersed power transformer will be damaged. There are two types of basic windings: concentric and overlapping.

3. Fuel tank

The body (winding and core) of the 315KVA oil-immersed transformer is installed in an oil tank filled with 35KV oil-immersed power transformer oil, and the oil tank is welded with steel plates. The fuel tank of the medium and small 35KV oil-immersed power transformer is composed of a box shell and a box cover, and the body of the 35KV oil-immersed power transformer is placed in the box shell, and the box cover can be lifted out of the body for maintenance.

Nature of the load

1) When there is a large number of primary or secondary loads, it is advisable to install two or more 35KV oil-immersed power transformers, and when any one of the 35KV oil-immersed power transformers is disconnected, the capacity of the remaining 35KV oil-immersed power transformers can meet the electricity consumption of primary and secondary loads. The primary and secondary loads should be concentrated as much as possible and should not be too dispersed.

2) When the seasonal load capacity is large, it is advisable to install a special 35KV oil-immersed power transformer. Such as air conditioning and refrigerator load in large civil buildings, heating electricity and heating load, etc.

3) When the concentrated load is large, it is advisable to install a special 35KV oil-immersed power transformer. Such as large-scale heating equipment, large-scale X-ray machines, electric arc furnaces, etc.

4) When the lighting load is large or the power and lighting use a common 35KV oil-immersed power transformer, which seriously affects the lighting quality and lamp life, a special 35KV oil-immersed power transformer for lighting can be installed. In general, the power and lighting share a 35KV oil-immersed power transformer.

The main faults of the winding of the 315KVA oil-immersed transformer are inter-turn short circuit and short circuit to the shell. The turn-to-turn short circuit is mainly caused by the aging of the insulation, or due to the overload of the 315KVA oil-immersed transformer and the mechanical damage to the insulation during the traversal short circuit. The oil level in the 315KVA oil-immersed transformer drops, causing the winding to expose the oil surface, and the inter-turn short circuit can also occur; In addition, when there is a crossing short circuit, the winding is deformed due to the action of overcurrent, and the insulation is mechanically damaged, which will also cause an inter-turn short circuit. In the case of turn-to-turn shorts, the current in the short-circuit winding may exceed the rated value, but the current in the winding as a whole may not exceed the rated value. In this case, the gas protection action, and when the situation is serious, the differential protection device will also act. Short circuits to the enclosure are also caused by aging insulation or oil moisture, drop in oil level, or due to lightning and operating overvoltage. In addition, in the event of a pass-through short circuit, the windings are deformed due to overcurrent, and a short circuit to the housing may occur. When the shell is short-circuited, it is generally the action of the gas protection device and the grounding protection action.