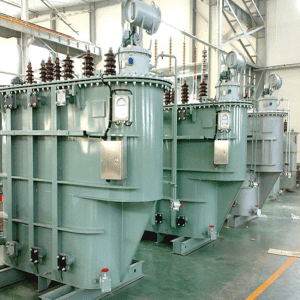

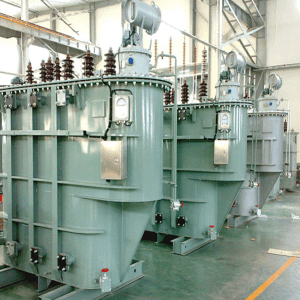

Product description

250KVA oil-immersed transformer is a new generation of low-noise, low-loss transformer developed in recent years, its core has no joints, greatly reduces no-load loss and no-load current, and reduces the no-load current by 60%~80% The high and low voltage coil is continuously wound on the core column, the winding is compact, the concentricity is good, and the anti-theft performance of the product is enhanced. The noise of 250KVA oil-immersed transformer is reduced by more than 10 decibels. The temperature rise is 16-20K lower. Due to the continuous winding of the iron core (the cross-section is pure circular), the orientation of the silicon steel sheet is fully utilized, and the no-load loss is reduced by 20%~30%.

250KVA oil-immersed transformer application range

1) Cities and large-scale industrial and mining areas such as high-rise buildings, underground buildings, airports, transportation hubs, communication and information centers, important municipal facilities, densely populated urban areas, commercial centers, etc., these places are generally supporting the use of 6~10kV power transformers and 35 kV power transformer.

2) Power plants, power plants, hydropower plants, nuclear power plants, power supply stations, hydropower stations, power supply systems, etc. S11 series oil-immersed transformers are suitable for power supply systems, power industry, metal products, construction industry, metallurgical industry, machinery industry, mining industry, textile industry, transportation and shipping, forestry system and many other fields

Advantages of 250KVA oil-immersed transformer

1. Energy saving and low noise

It is stacked with high-quality cold-rolled silicon steel sheets, which has the advantages of high magnetic permeability and low loss; The coil is left with a ventilation groove, and the air flow is smooth, which effectively reduces the temperature of the coil; The use of special resin impregnated paint, and then heated at high temperature, increases the heat resistance of the transformer, making the transformer more energy-saving and quieter.

2. High reliability

Isolate the power supply of the main power grid, anti-shock, anti-interference, anti-lightning. A large number of basic research has been carried out in the quality assurance system and reliability engineering, and the reliability certification has been actively carried out to further improve the reliability and service life of the transformer.

3. Environmental protection characteristics. It has heat resistance, moisture resistance, stability, chemical compatibility, low temperature resistance, radiation resistance and non-toxicity.

4. Large capacity. In order to meet the needs of each user as much as possible, we have set up a transformer from 10~1000kVA.

250KVA oil-immersed transformer product performance:

The energy-saving effect is particularly significant, and the no-load loss rate is reduced by about 30% compared with that of S9 series oil-immersed transformers; The S11 series transformer has stronger short-circuit resistance, the high-voltage winding is wound by high-quality oxygen-free copper rod-drawn wires, and the low-voltage winding adopts a spiral structure with axial oil channels; The assembly of the transformer body and the winding winding are completed in the fully enclosed purification workshop, which meets the cleanliness requirements and constant temperature requirements of the body for the manufacture of 250KVA oil-immersed transformer products. In addition, rigid positioning is used for specific positions to ensure the stability of the product; The fuel tank is corrugated by a large plate folding machine to reduce welds, prevent leakage, enhance mechanical strength, expand the heat dissipation area, and prolong the service life of the transformer oil tank. In short, the company makes the products always maintain low partial discharge, low noise, low loss and high reliability.

Executive Standards:

GB 1094.1-1996 GB 1094.2-1996 GB 1094.3-2003 GB 1094.5-2003 GB /T6451-1999 GB /T10237-1988 GB /T3837-1996 GB /T7595-2000