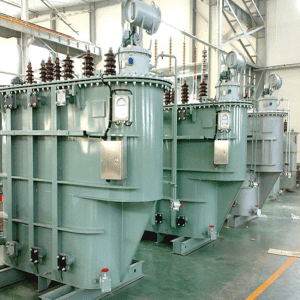

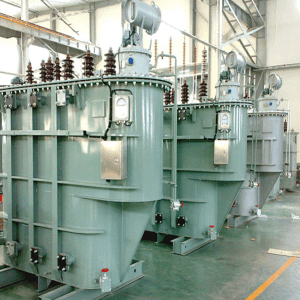

Product description

1.2000KVA oil-immersed transformer technology is advanced, safe and reliable

The 2000KVA oil-immersed transformer box part adopts the current domestic leading technology and technology, the shell is generally made of aluminized galvanized steel plate, the frame is made of standard container materials and production technology, which has good anti-corrosion performance and ensures that it does not rust for 20 years, the inner sealing plate is made of aluminum alloy gusset plate, the interlayer is made of fireproof and thermal insulation materials, the box is equipped with air conditioning and dehumidification devices, and the equipment operation is not affected by the natural climate environment and external pollution. It can ensure normal operation in the harsh environment of -40°C~+40°C.

The primary equipment in the box adopts domestic technology-leading equipment such as unit vacuum switch cabinet, dry-type transformer, dry-type transformer, vacuum circuit breaker (spring operating mechanism), etc., the product has no exposed live part, is a fully insulated structure, and can achieve zero electric shock accidents, and the whole station can realize oil-free operation with high safety.

2 2000KVA oil-immersed transformer has a high degree of automation

The intelligent design of the whole station, the protection system adopts the microcomputer integrated automation device of the substation, and the decentralized installation can realize the “four remotes”, that is, telemetry, remote signaling, remote control, remote adjustment, each unit has independent operation function, and the relay protection function is complete, and the operating parameters can be set remotely, and the humidity and temperature in the box can be controlled to meet the requirements of no one on duty.

3. Factory prefabrication

When designing, as long as the designer makes a main wiring diagram and the design of the equipment outside the box according to the actual requirements of the substation, the specifications and models of the box transformer provided by the manufacturer can be selected, and all the equipment is installed and debugged in the factory at one time, so as to truly realize the factory construction of the substation and shorten the design and manufacturing cycle; The on-site installation only needs box positioning, cable connection between boxes, outgoing cable connection, protection value verification, transmission test and other work that needs to be commissioned, and the whole substation only takes about 5~8 days from installation to operation, which greatly shortens the construction period.

4. Flexible combinations

Due to the compact structure of the 2000KVA oil-immersed transformer, each box constitutes an independent system, which makes the combination flexible and changeable, we can all use the box-type, that is, the 35kV and 10kV equipment are all installed in the box to form a full box-type substation; It can also be installed outdoors with 35kV equipment, installed in the box of 10kV equipment and control and protection system, this combination is especially suitable for the transformation of the old place in the transformation of the rural network, that is, the original 35kV equipment is not moving, and only a 10kV switch box can be installed to meet the requirements of unattended.

5. Economical investment and quick results

The 2000KVA oil-immersed transformer (35kV equipment is arranged outdoors and installed in the 10kV equipment box) reduces the investment by 40%~50% compared with the integrated substation of the same scale (35kV equipment is arranged outdoors, and 10kV equipment is arranged in the indoor high-voltage switchroom and central control room).

1.1.6 Small footprint

Basic technical data of 2000KVA oil-immersed transformer

|

|

project |

unit |

parameter |

|

High voltage |

Rated frequency |

HZ |

50 |

|

Rated voltage |

KV |

6 10 35 |

|

|

High operating voltage |

KV |

6.9 11.5 40.5 |

|

|

Power frequency withstand voltage |

KV |

32/36 42/48 95/118 |

|

|

Lightning impulse withstand voltage |

KV |

60/70 75/85 185/215 |

|

|

Current rating |

A |

400 630 |

|

|

Rated short-time withstand current |

KV |

12.5(2S) 16(2S) 20(2S) |

|

|

Rated peak withstand current |

KV |

31.5 40 50 |

|

|

Low pressure |

Rated voltage |

V |

380 220 |

|

Rated current of the main circuit |

A |

100~3200 |

|

|

Rated short-time withstand current |

KV |

15 30 50 |

|

|

Rated peak withstand current |

KV |

30 63 110 |

|

|

Tributary current |

A |

10~800 |

|

|

Number of branch circuits |

road |

1~12 |

|

|

Compensation capacity |

KVAR |

0~360 |

|

|

Transformer section |

Rated capacity |

KVA |

50~2000 |

|

Short-circuit impedance |

% |

4 6 |

|

|

Tap range |

|

±2×2.5%±5% |

|

|

Joining groups |

|

Yyn0 Dyn11 |